Delivery Systems

Electronic Data Interchange

EDI - Jointly benefit

Gartner Research shows that correcting an error during the order process is 10 to 15 times more likely than the order process itself. Although EDI has been an established process for many years, the number of messages transmitted continues to increase. Rutronik‘s EDI portfolio is as diverse as our customers‘ industries and markets. Rutronik speaks its customers‘ language. And Rutronik supports the individual EDI situation. Many different message types, all established EDI forms and the most important transmission channels are familiar to Rutronik‘s EDI experts and part of their daily business. Together with the partner, a dedicated team at Rutronik analyzes the requirements and the current situation. They develop an individual solution to create a win-win situation. During the definition Rutronik‘s experts follow tried and tested processes and procedures when defining the details and setting up the connection. Of course, they have the flexibility to react to special requirements or situations.

List of documents Rutronik is exchanging with its suppliers

- Orders

- Order confirmations

- Order changes

- Delivery notes

- Invoices

- Stock information

- Availability information

- Sales reports

- Ship & debit reports

- Logistic reports

- Price lists

- Forecast information

Content format

To enable automatic import into the customer‘s IT system, the data must be converted to a standard format. Worldwide many different types are in use.

Rutronik can handle the most important ones:

- UN/EDIFACT

- VDA

- XML

- SAP-IDOC

- OpenTRANS

- ebXML

- RosettaNet

- XLS

- CSV

- TXT

- …

List of documents Rutronik is exchanging with its customers

- Forecast information

- Orders

- VMI handling

- Consignment removal

- Consignment refill orders

- Delivery notes

- Invoices

- Consignment

- Order confirmation

- Order change

Message format

Standard protocols have been defined for a reliable transfer of data between sender and recipient.

Rutronik supports all established variations:

- AS2

- FTP/FTPS

- VANs

- X400

- OFTP

- SMTP (Email)

- …

Process Visualization for Tailor-Made Systems

Increasing efficiency along the supply chain

Over the past decades, Rutronik has continuously developed tools to implement, improve, and monitor forecasting processes with all partners along the supply chain. Today, we have a flexible system that allows us to change key process parameters at the click of a mouse to respond as quickly as possible to the daily challenges that affect the supply chain.

Our delivery simulation tools allow us to test the entire supply chain process before going live with the EDI interface. In addition, the average inventory levels are calculated and visualized to provide a 360-degree view of the material flow

Smart delivery systems rely on a large amount of information. This data can change daily on both the customer and supplier side, increasing the complexity of our daily business.

In order to always have a complete overview of the situation, we have developed individual tools and dashboards that provide us and our and our customers in a valuable way.

Bringing together data from the past and the coming months together in the right context is essential to make the best decisions for the future today.

C-Parts at Rutronik

Increasing efficiency along the supply chain

When looking at the total cost of ownership, it becomes clear that C-parts management in particular can benefit from the advantages of modern logistics systems. This is because tailor-made, automated logistics solutions not only guarantee the availability of materials, but also simplify and accelerate procurement processes, thereby reducing process costs.

C-parts management is subdivided into the administrative area of ordering and, on the other hand, the physical movement of goods. Orders are placed via the use of the EDI (Electronic Data Interchange) data interface and one of the three models consignment, Kanban, and scheduling agreement. These three process control tools can also be combined or optimized through the use of VMI (Vendor Managed Inventory) models. With these models, the supplier has access to the customer‘s inventory and demand data of the customer, which significantly improves efficiency in the supply chain. Thanks to automation, the logistics processes are also less error-prone and process quality increases.

The cost of physically moving the goods can be reduced by bundling the quantities. In larger delivery batches the requirements over several weeks are grouped together and delivered instead of small weekly quantities. The Rutronik ERP automatically adds up the jointly defined quantities.

This reduces process costs considerably, as many steps are eliminated - from ordering, goods receipt and collection to subsequent invoice verification.

Another bundling option is to use larger packaging units - common sizes range from 5,000 to 50,000 units. In the chip resistor sector in particular, this also has a positive effect on the set-up times of SMD machines: If a company changes for example, from a roll size with 5,000 resistors to a pack of 10,000, the set-up costs are halved.

With an annual requirement of several million or even billions of a component, this adds up to a greatly reduced number of packages or pallets, a considerable acceleration in incoming goods and therefore a significant reduction in throughput times.

Consolidation with potential

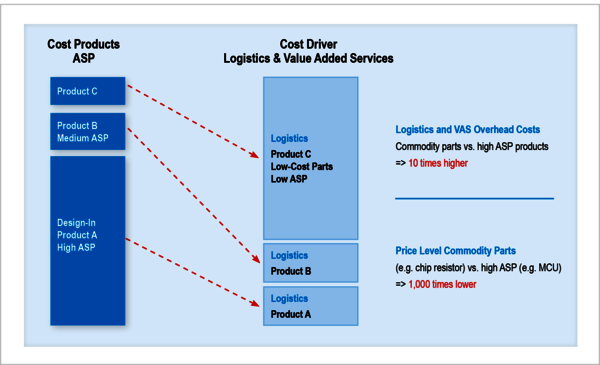

The average selling price (ASP) of electronic components varies significantly depending on the product group. When it comes to C-parts such as resistors and capacitors, companies face significantly higher inventory and consulting costs despite a lower selling price. Compared to high-value components, the costs are ten times higher - with a sales price that is a thousand times lower.

Rutronik‘s overall cost structure is also based on C-parts - but customers can only achieve real savings if they not only purchase C-parts, but also other components from our portfolio.

After all, higher volumes create maximum synergies. The supply chain solutions at Rutronik focus on C-parts. Keeping the costs of the entire process as low as possible, from ordering to assembly on the SMD line, is our main goal.

Our team of experienced Supply Chain Managers will advise you and work with you to develop the perfect concept to suit your company and processes.

Comparison of the relative total costs for Design-In parts vs. low ASP components