Focus on availability: Logistics with a system - security of supply and process cost optimisation

Fierce competition, increasing cost pressures, shorter product lifecycles, and widely varying delivery times require new solutions. Logistics solutions that help you produce faster, more cost-effectively, and above all, uninterrupted.

Rutronik has been a distributor for electronic components for more than 50 years. As an owner-managed and therefore independent company, Rutronik is one of the world‘s leading leading broadline distributors. The last few years in particular have shown how fragile the global supply chain is. Rutronik as a globally operating distributor, faces these challenges every day with its Supply Chain Management. We would like to take you with us and give you insight into the core processes of Rutronik Supply Chain Management, from procurement to our supply chain solutions powered by Electronic Data Interchange to our warehouse.

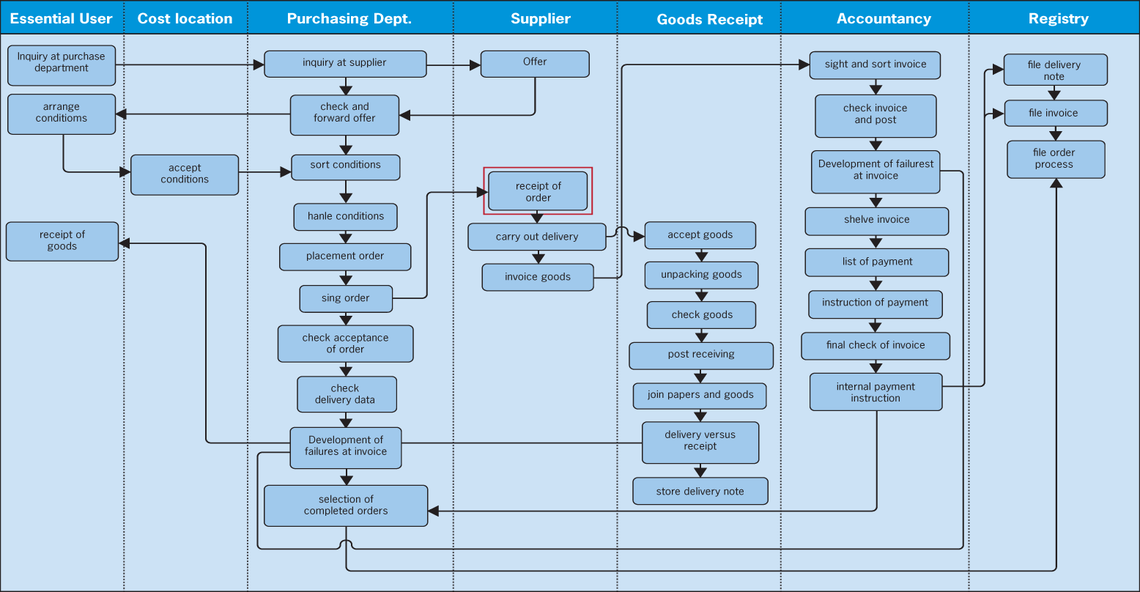

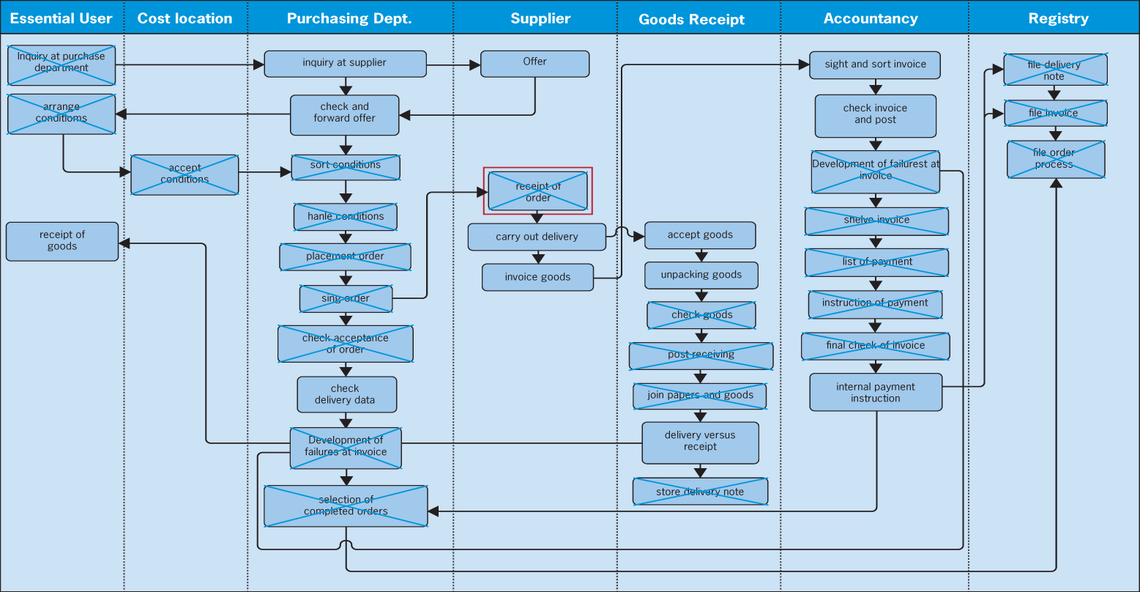

Procurement

Flow of information in real time

In today‘s world, fast changing demands, shortages and other impacts from geopolitical events or natural disasters are the daily challenges of the modern procurement. The procurement process at Rutronik is supported by a wide range of Electronic Tools which make this process as fast, automatic and efficient as possible.

- Our ERP system calculates the right quantity for the right time and automatically transmits the order via EDI directly to the manufacturer‘s system.

- The manufacturer confirms the delivery date via EDI and sends a shipping notification as soon as the shipment leaves their warehouse

This gives us a high level of visibility into the status of your order at all times. Increasing or decreasing lead times, transportation time, or global shipping situation has a huge impact on our supply chain and is therefore one of our main focuses.

Stock Management

Our Strategic Materials Management team is constantly developing new sourcing processes and strategies. Our main focus is to fulfill our commitment to deliver. The Second Source Strategy supports this approach. Based on our overview of demand, fluctuation, free available stock and future incoming quantities, we are able to support our customers as flexibly as possible. In addition, employee training ensures a high level of performance in a changing market.

Warehousing in a decentralized Rutronik organisation

Rutronik‘s global warehouses in Europe, Asia, and the Americas give us the ability to source materials locally to reduce lead times, increase availability, and decrease the carbon footprint due to shorter transport distances. All warehouses share the same high level of service and are linked by a global ERP system. Our growing team of material planners, product marketing, and logistics experts around the world are another essential part of the procurement process. With the decentralization of some key procurement functions to local regions, Rutronik has laid the foundation for future growth and the best possible support for our customers.

Distribution as a service

Broadline distribution is more than just the purchase and sale of electronic components. Rutronik is a highly professional partner for all aspects within the supply chain.

- Our consulting expertise has technical roots: it starts with the selection of the right, efficient, and available products.

- Our electrical engineers assist customers with end-of-life management, obsolete, or required software.

The decentralized organization is able to focus on any type of customer size or industry. This also includes multi-business covering all business partners such as manufacturers, end customers, OEMs, or EMSs. Our strong customer and manufacturer network results in a high level of flexibility and security, creating a win-win situation for all our partners. Finally, our smart tailor-made logistics solution supports our customers worldwide.

Warehouse Logistics

Outstanding performance: the big plus of distribution

The warehouse and logistics center includes approximately 8,600 m² of storage and order picking space. There are also three platforms with approximately 6,000 m² of storage space. This provides space for up to 11,000 pallet locations, approximately 185,000 normal rack locations, and an order buffer of approximately 3,000 locations. The latest building and energy technology has been incorporated to ensure maximum energy efficiency, while a photovoltaic solar panel system has been installed on the roof. This generates peak values of up to 1 megawatt. Approximately 60% of the total energy is used for consumption. The option to add two concrete floors for future conversion ensures that the building is future-proof and sustainable. Thanks to the modular design of the overall system, individual areas such as the order buffer, the manual and automatic high-bay storage system, the conveyor technology for the new racking area and the semi-automated goods receiving area, can be tested extensively, independently of current operations before each of the sub-processes is carefully transferred to production.

The design of the storage facility focused heavily on maximum availability. In the event of a power outage, an emergency power supplies 1.2 megawatts of power. The building itself, the conveyor technology and the software, is supplied by the emergency power supply.

Every movement process is designed to allow for manual solutions in the event of an emergency.

Rutronik now has two new peer computer systems in mirrored operation: Two fiber optic cables supply power from two different junction points. This guarantees a secure data connection. We use LED technology to illuminate many areas of the building. Peripherals such as cables and control cabinets have also been reduced in number, creating a further gain.

With the new building, we have created the conditions that will enable us to meet our customers‘ needs in the future and stay ahead of the competition.

Availability Focused in Logistics Systems - Get Security of Supply and Process Cost Optimization

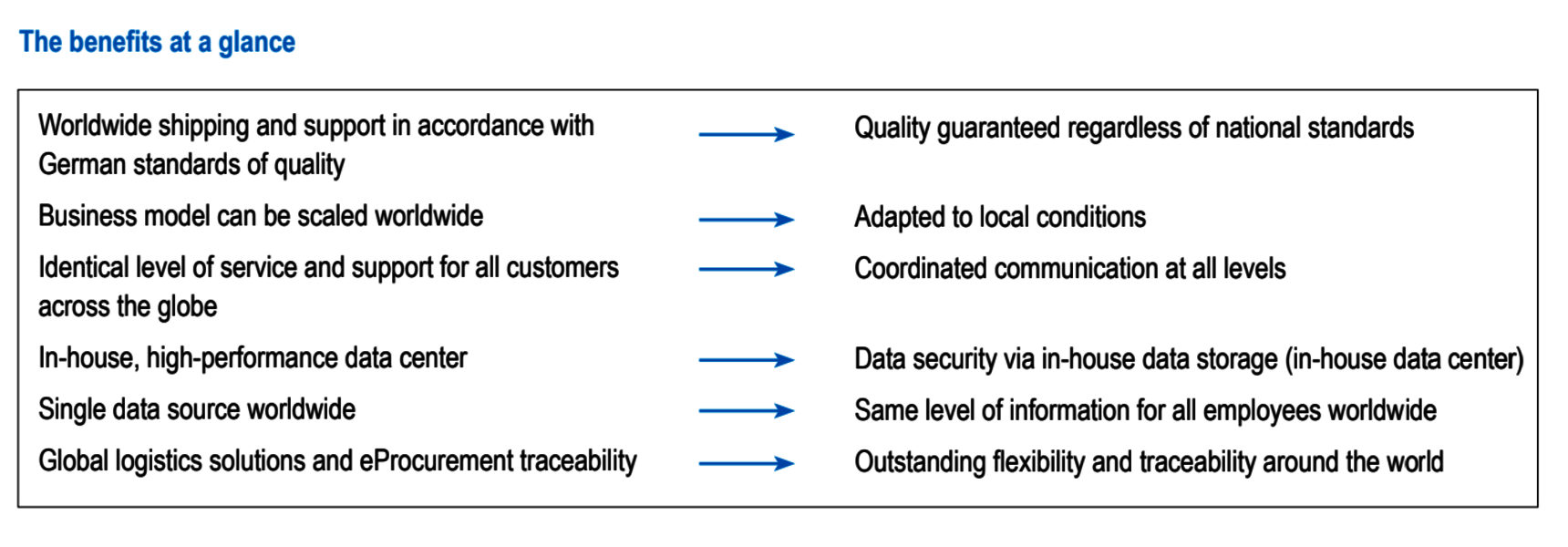

Benefit from Rutronik added values: We have years of implementation and optimization experience with supply chain solutions. We develop logistics solutions, which are based on the method of "best practice". With these intelligent, predefined standards our customers are ready to start.

Advance by way of professional logistics systems

The market for electronic components places the highest of demands on logistics. On the one hand, broadliners need to cope with widely differing volumes of product quantities from a huge product range.

The market is also characterised by heavy requirement fluctuations, which in part give rise to very long delivery periods spanning several months.

The alternation between scarcity and over production calls for timely intervention, where possible, to guarantee reliable and trouble-free supplies. This is where the advantages of tailor-made, uniform, logistics systems come into effect:

- High level of automation

- Reduction in labour input

- Reduction in process costs

The proper functioning of a logistics system is conditional on the electronic exchange of data that allows for a swift reaction to changes in requirements. At the same time processes are optimised and errors reduced. Ultimately, recording and confirming orders manually is a potential source of errors.

The advantages of our logistics system

Increased supply security

A medium to long-term requirements forecast and procurement and capacity planning are necessary to achieve a high level of supply security. During the ongoing exchange of information this is refined on an ongoing basis and adjusted in line with the plan data.

Among other things, this means the following advantages:

- Reduction in the dependency on the replacement time because scheduling is based on the customer's forecast figures

- Flexibility: in the case of fluctuations in requirements, customers can postpone and reduce order quantities within the agreed window.

Reduction in process costs

- The processes are analysed in detail in the run-up, optimised and reset:

- Reduction of labour-input by manual activities

- Management by exception: communication only in the event of variations, and intervention or adjustment regarding orders.

- Orders are bundled by way of collective deliveries

- The item label on carton saves individual delivery note allocation. The label contains all details for easier collection and processing.

Individual and nevertheless efficient

Logistics to meet your needs: we therefore gear our operations towards the specific requirements of your company. For example the step-by-step adjustment of partial solutions has proven successful in the case of introducing a logistics system. At Rutronik we don't use rigid concepts.

Increase in quality within the processes

Error reduction and greater process security thanks to automated data and interface exchange.

Reduction in capital tie-up costs in the Supply Chain

By way of optimised store management between customers, manufacturers and Rutronik, stocks in finished and buffer stores are kept low. This ties-up less capital, and processing costs are reduced considerably - without jeopardising the ability to deliver. Likewise, the reduction in the number of suppliers is, without doubt, one of the key steps in respect of increasing efficiency and saving costs in the case of procuring electronic components. Many customers therefore make use of the advantages offered by a broadline distributor such as Rutronik. As an interface to leading and established manufacturers, Rutronik covers the entire range of electronic components.