Supply Chain Solutions

Advance by way of professional logistics systems

Advantage through professional logistics systems

The electronic components market places the highest demands on logistics. First and foremost, broadliners must be able to handle very widely differing product volumes from a wide range of products. The market is also characterized by strong fluctuations in demand, which can result in very long delivery times of several months. The alternation between shortages and overproduction requires timely intervention to ensure reliable and smooth supply.

This is where the benefits of tailor-made and unified logistics systems come into play:

- High level of automation

- Reduction in labour input

- Reduction in process costs

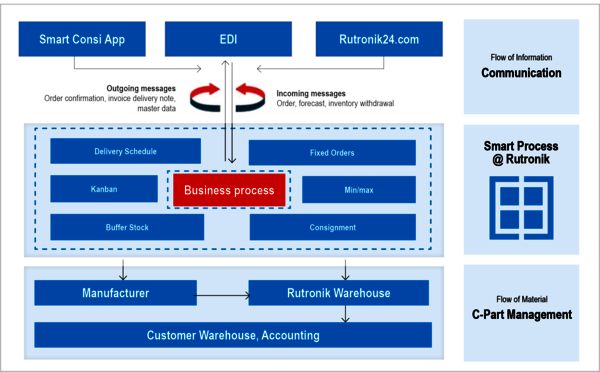

The proper functioning of a logistics system depends on the electronic exchange of data, which enables to respond quickly to changing requirements. At the same time, processes are optimized and reduce errors. After all, manual order entry and confirmation is a potential source of error. of errors.

Increased supply security

In order to achieve a high level of supply security, a medium- to long-term demand forecast as well as procurement and capacity planning are necessary. These are continuously refined and adjusted to the planning data in a continuous exchange of information. Among other things benefits include the following:

- Reduced dependency on replacement time, as scheduling is based on customer forecast figures

- Flexibility for fluctuating demand, as customers can shift and reduce order quantities within the agreed window

Process cost reduction

The supply process is analyzed in advance, optimized and defined together with the with decision makers:

- Reduction of labor input for manual activities

- Management by exception: communication only in the event of deviations and intervention or adjustment of orders

- Orders are bundled by means of collective deliveries

Individualized yet efficient

Logistics tailored to your needs is why we tailor our activities to the specific needs of your company. For example, the step-by-step adaptation of partial solutions has proven its worth when introducing a logistics system. At Rutronik, we don‘t work with rigid concepts.

Improve the quality of processes

Reduce errors and increased process reliability with automated data and interface exchange.

Decision criteria

- Demands/trends

- Concentrated deliveries

- Supply security

- Parts availability

- Process costs

- Optimized Inventory

- Bond capital

- Automation (e. g. EDI)

- Flexibility

- Lead time reduction

- Stock capacity

- Packaging solutions

Reducing the cost of capital tied up in the supply chain

Thanks to optimized inventory management between customers, manufacturers, and Rutronik, inventories in finished goods and buffer stocks are kept low. As a result, less capital is tied up and processing costs are significantly reduced - without jeopardizing the ability to deliver. The reduction in the number of suppliers is undoubtedly one of the most important steps towards increasing efficiency and saving costs in the procurement of electronic components. Many customers therefore take advantage of the benefits offered by a broadline distributor such as Rutronik. As an interface to leading and established manufacturers, Rutronik covers the entire range of electronic components.

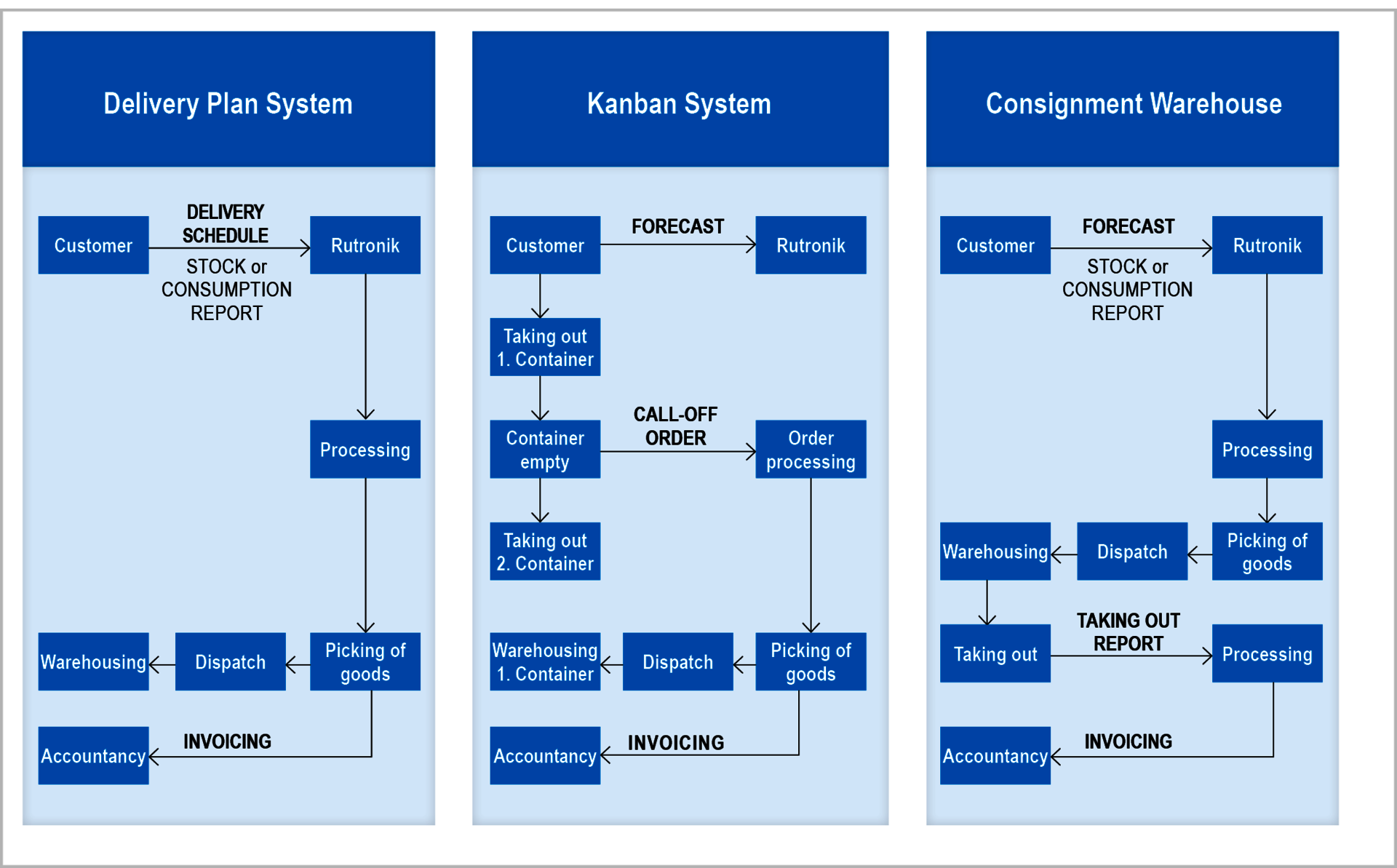

Delivery Plan System | Kanban | Consignment Warehouse

Flexibility without limits

Process cost reduction

Delivery systems

As a broadliner, Rutronik generates half of its total sales with logistics systems and supports logistics customers worldwide.

Orders are prepared and coordinated at the company‘s headquarters in Ispringen, Germany, so that Rutronik can offer the same service standards in terms of uniform labels, packaging, notification, and much more.

This is based on three standardized logistics systems that are easy to implement: „Delivery Plan System“, „Kanban“, and „Consignment“ with defined processes for the flow of information, materials, and values. They are adapted to the customer‘s processes, costs and factors, and can be flexibly combined with system support for forecasting, ship-to-line, barcodes, and many other additional options.

The result is a tailor-made solution.

Smart Processes

There‘s a solution for every challenge

Delivery Plan System

Smart and simple

Delivery schedule processing can be applied to all components and is suitable for a small number of product numbers. The customers forward their planned figures (forecast) to Rutronik on a rolling basis at fixed intervals.

This forecast forms the basis for scheduling. Based on the planned figures, Rutronik supplies all divisions within a defined window, and these are „fixed“ according to the definition agreed with the customer. The demand patterns can be irregular.

- Can be used for all components

- Highly flexible system (even in the event of requirement changes)

- Effective C-parts management through optimized delivery quantities

- Low labor costs

Kanban

“Card System” for secure product circulation

Kanban processing is suitable for constant requirements in the case of continual production processes. The Kanban containers are defined in the run-up with a certain filling quantity, likewise their quantity. Each container has a clear identity number. All details on a container (quantity, parts no., warehouse location, recipient warehouse and delivery time etc.) are listed on a “Kanban card”. Two containers are in operation as a minimum to guarantee product circulation. As soon as a Kanban container is empty at a customer’s premises, the electronic Kanban card is forwarded to Rutronik, the container is refilled and the delivery process starts afresh. The Kanban containers are made available directly at the place of use.

- Self-operated control loop

- Reduced material inventory and capital tie-up

- Reduced throughput times

- Can be combined with multi-use container system

Consignment Warehouse

Flexible and reliable

The consignment warehouse is an ideal solution for production subject to short-term fluctuations. While the customer merely provides the storage space, Rutronik provides the goods. Invoices are only written out once goods are withdrawn from the warehouse. Stocks without warehouse evaluation are kept separately. Customers are therefore required to display the warehouse by way of EDP technology, and information can be exchanged electronically. Various models are available for filling the consignment warehouse, such as consumption-controlled min/max filling or requirement-controlled via forecasts.

- High availability and supply security

- Low processing input

- Reducing capital tied up in the supply chain

- Vendor managed consignment inventory

- Centralised inventory controlling via our specialist department

- Also available as an app