Revolution is Coming

"Supercaps can revolutionize the energy accumulator world!"

Prof. Dr. Eng. Mirko Bodach (Professor for electrical engineering / renewable energies at 'Westsächsische Hochschule Zwickau')

Battery-driven applications are common in many market segments, such as the automotive sector, in the field of electromobility, in uninterrupted power supplies (UPS) and many other fields. Here, the demands in terms of performance and operating life are very high. This is where so-called supercaps, also known as ultracaps or EDLCs (Electric Double Layer Capacitors), have many advantages compared with conventional lithium-ion accumulators. The Field Application Engineers from Rutronik Elektronische Bauelemente GmbH provide an intensive and comprehensive range of consultancy services regarding the fields of application, ranging from project planning phases to their realization. Also, Rutronik has a wide range of supercaps in its portfolio.

They can be ordered online via the eCommerce platform www.Rutronik24.com. This page gives you an introduction to the features, potential areas of application and the advantages of EDLCs.

What are Supercaps?

What are Supercaps?

Supercaps are safe, robust and durable: EDLCs - i.e. Electric Double-Layer Capacitors, also known as supercaps or ultracaps - have many advantages over lithium-ion accumulators. They are very versatile and can be used in applications as diverse as energy supply technology and consumer devices.

Supercaps are electric capacitors with an unusually high power density. In comparison with conventional electrolytic aluminum capacitors supercaps have a thousand times higher capacity and energy density. In comparison with lithium-ion batteries, ultracapacitors have considerably more power and a higher durability. EDLCs are especially good for applications that require much more output performance than a lithium-ion battery alone can deliver. In such applications, the supercap functions by way of peak-power support, with the peak performance being supplied by the EDLC. This takes the strain off the lithium-ion battery and increases its service life. As an example, such a hybrid system can be found in a cordless screwdriver.

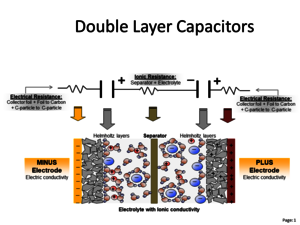

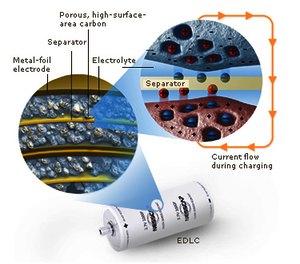

How do Supercaps Work?

A supercap consists of two non-reactive porous carbon electrodes on current collectors that are immersed in an electrolyte system with a voltage potential applied across the collectors. In an EDLC cell, the potential applied on the positive electrode attracts the negative ions in the electrolyte, while the same potential at the negative electrode attracts the positive ions. A dielectric separator prevents the two electrodes from creating a short circuit. The amount of energy stored is very large compared to a traditional capacitor due to the enormous surface area that is available on the porous carbon electrodes.

Though EDLCs are regarded as electrochemical devices, no chemical reactions are involved in the energy storage mechanism: Instead, a highly reversible physical phenomenon is involved, and this is what gives EDLCs their extremely long cycle life. Since the rates of charge and discharge are dependent only upon the physical movement of ions, the ultracapacitor can store and release energy much faster.

In contrast to classical EDLCs, the Nesscap Pseudocapacitor is a combination of supercap and high energy battery. This special configuration combines the quick energy release of an EDLC with the higher storage capacity of a chemical battery. In a pseudocapacitor cell, one of the two porous carbon electrodes is replaced with such materials as metal-doped carbons, conducting polymers, or metal oxides. This results in two different charge mechanisms at the electrodes: electric double layers at the porous carbon electrode and a combination of faradaic and surface reactions occurring at the high energy electrode. This combination produces a charge transfer behavior that is linearly dependent upon the applied voltage, and, as a result, the pseudocap functions and behaves like a capacitor.

Nesscap's Pseudocapacitors typically have little less than double the energy of supercaps of similar physical dimensions, whereby the defined cycle life is not as much as that of the supercaps, but considerably more than with lithium-ion batteries. For applications in which heavy-duty cycling is not the highest priority, such as in uninterruptible power supplies (UPS) or other power backup applications, using pseudocapacitors can be the optimal solution.

What Special Features do Supercaps Have?

Compared with standard accumulators, ultracapacitors have various advantages that make a range of applications possible:

|

Parameters |

Electrostatic Capacitor |

Ultracapacitor |

Battery |

|

Discharge Time |

10-6~10-3 sec |

1-30 sec |

0.3~3hrs |

|

Charge Time |

10-6~10-3 sec |

1-30 sec |

1~5hrs |

|

Energy Desity (Wh/kg) |

<0.1 |

1~10 |

20~100 |

|

Power Density (W/kg) |

< 10,000 |

10,000 |

50~200 |

|

Charge /Discharge Efficiency |

~1.0 |

~1.0 |

0.7~0.85 |

|

Cycle Life |

Infinite |

> 500,000 |

500~2,000 |

Safe and Robust

Safety issues associated with the use of EDLCs are practically negligible in comparison with lithium-ion batteries. Whereas the electrical properties of lithium-ion batteries are such that safety thresholds can easily be exceeded and exothermic reactions must be reckoned with, especially when they are not used properly, EDLCs have proven to be significantly more robust and safe. Researchers from the University of Applied Sciences Zwickau have carried out so-called 'abuse tests' on supercaps, and so far they have not found any case in which the destruction was associated with any safety-relevant problems.

In contrast to lithium batteries, deep discharging is uncritical. On the other hand, supercaps should not be overcharged, because that greatly reduces their service life and can damage the capacitor irreversibly. Further, it is possible that a short-circuit in the electrical switching could bring about a hazard during usage of the ultracapacitor. Even in relatively small designs, the very low internal resistance could allow high short-circuit currents to flow. For this reason it is advisable to use appropriate protective elements such as fuses for interrupting the faulty circuit.

Which Areas of Application Benefit from Supercaps?

While many applications can benefit from supercapacitors, the applications that benefit most from them are ones that require quick charging and discharging with a large amount of energy and high currents. For example, only ultracapacitors can capture and store large amounts of re-generated electrical energy during braking and release them quickly for re-acceleration in hybrid vehicles.

Even with a minor role in today's micro- to mild-hybrid cars, the energy savings can yield up to 15% in fuel savings. In energy storage systems for electrical trains, trams, and subways, those savings can easily add up to 25% savings in energy consumption.

Ultracapacitors also perform well in supporting roles as they can be used in conjunction with batteries and fuel-cells to enhance the performance and the service life of the overall system. Using ultracapacitors in conjunction with batteries combines the power performance of the ultracapacitors with the greater energy storage capability of the batteries. This can extend the life of the batteries, while enhancing the overall performance by increasing the available energy for high peak power.

The ultracapacitor has great growth potential because it is oriented to key markets that also address societal needs of our time: It is environmentally friendly, helps conserve energy, and enhances the energy-saving performance of other devices when used in conjunction with other technologies.

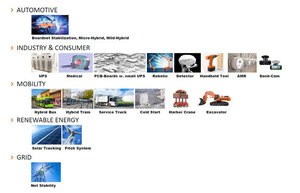

In Which Market Segments Can Supercaps be Used Most Advantageously?

You will find examples of application areas that can profit from supercapacitors in the following section:

Automotive: boardnet stabilization, micro-hybrid, mild-hybrid

Industry & Consumer: UPS, medical, PCB boards with small UPS, robotics, detectors, handheld tools, AMRs, dash cams

Mobility: hybrid buses, hybrid trams, service trucks, cold start, marine, electric harbor cranes, excavators

Renewable Energy: solar tracking, pitch control system

Grid: Net and frequency stability in isolated or combined networks

- Battery replacement

- Safety-relevant & back-up applications

- High power requirement

- Enough energy to rotate the blades in case of shut-down

- Reliable in extreme environments

- Wide range of temperature (-40°C -> +85°C)

- Wide range of temperature (-40°C -> +85°C)

- Negligible maintenance cost

- Lasts longer than a battery

- Lasts longer than a battery

- Eco-friendly

- Lightweight

- Battery augmentation

- Levels / Caps peak demands on battery

- Peak power solution

- Bridge power

- High power requirement

- Enough energy to cover the time required

- Peak shaving

- Levels short peak demands on the power grid (not load leveling)

- Negligible maintenance cost

- Longer battery service life

Some possible application areas

Power quality: Smooth out peaks and dips in the voltage input

Memory backup: Save process and location information to resume working

Power backup: Backup power to finish immediate process step before final power failure

How can Rutronik’s Supercap Expertise Help your Company?

Rutronik does more than just market EDLCs: We provide face-to-face and on-site support to customers from the planning phase right up to project completion. In addition we offer seminars covering subjects like POWER or H.E.S.S. (Hybrid Energy Storage Systems) - a platform for transferring knowledge and exchanging ideas with our product specialists and suppliers. We are cooperating with the University of Applied Sciences Zwickau on a research project, so we remain at the cutting edge both from the practical as well as theoretical points of view and contribute towards the further development of better energy storage systems. A H.E.S.S. 'demoboard' is currently under development with a view to being able to demonstrate the benefits of hybrid energy storage systems to our customers.

Our plus-points for you at a glance:

- Reliable and competent contact persons / product specialists for supercaps

- Close contacts to leading suppliers across the globe

- Worldwide logistics services

- Technical support for developers (including locally with customers), with and without suppliers

- The only broadline distributor who is actively promoting the XP series together with Nesscap

- Availability and short lead times: All Nesscap articles with small (3F to 50F) and medium capacities (100F to 360F) in stock including the XP series (3F to 50F)

Electrochemical double layer capacitors can replace lithium-ion batteries in certain areas

Revolutionizing Energy Storage

They are safe, robust, and long-lasting: Electrochemical double layer capacitors, or EDLCs, also referred to in the trade as supercaps or ultracaps, have many advantages over lithium-ion batteries, and are suitable for numerous fields of application - from power supply technology all the way to consumer devices. Despite this, EDLCs still occupy a niche position on the energy storage market. Prof. Dr. Eng. Mirko Bodach of the University of Applied Sciences Zwickau has been conducting research into the versatile energy accumulators for almost 20 years. In this interview, he talks about the risks and advantages of as well as the reasons for the expected breakthrough of EDLCs.

Prof. Dr. Eng. Mirko Bodach

Prof. Dr. Eng. Mirko Bodach was appointed Professor of Electrical Energy Technology / Renewable Energy at the University of Applied Sciences Zwickau in 2007. For 19 years, he has investigated electrical energy accumulators for renewable energy systems, among other things, and is one of the first people to have used EDLCs in these types of systems. Bodach and his team of twelve research assistants are currently focusing their research on projects covering intelligent, stationary power-supply components, energy and storage management and much more.

You are doing research on EDLCs as well as lithium-ion batteries. Where is your main emphasis here?

Prof. Dr. Eng. Mirko Bodach: We use energy accumulators in different electrical application scenarios. In proportionate terms, EDLCs and traditional accumulator types such as batteries - lithium-ion batteries, and sometimes lead-based systems - are roughly balanced. Lead batteries are still very cheap and have been established in stationary applications for over 100 years.

For example, we are working on an interesting project about the combination of EDLCs and batteries in combined heat and power units. Publications about this are due shortly. The aim of the project was to improve the parameters of larger types of batteries by using EDLCs. In addition to performance, service life, robustness, charging capability, these include general acceptance as well as the normative prerequisites for the use of corresponding dual accumulators. Achieving the stated objectives there will allow developers to use the advantages of a technology with EDLCs more frequently.

What does that mean?

Bodach: The lack of standards and regulations in particular is fueling the uncertainty among development customers. Testing institutions ultimately need standards in order to conduct valid and reproducible safety tests, for instance, regarding explosion and fire risks as well as short-circuit risks. They must know which exogenous and endogenous factors can create risks. There is a need for continuous research in this area.

What risks exist compared with other energy accumulators?

Bodach: The safety risks arising from the use of EDLCs have proven to be minimal when compared with those of lithium-ion batteries. Whereas lithium-ion batteries can very quickly reach their limits in electrical terms and since allowances must be made for exothermic reactions, especially as a result of improper handling, EDLCs prove themselves to be a much more robust and much safer component in this regard.

In our abuse tests, we have not yet damaged an EDLC electrically in such a way that its destruction could have caused safety-relevant problems.

The creation of a "combustible" atmospheric oxygen gas mixture (from the electrolyte) in an enclosed room would require more EDLCs than would actually fit in the available installation space to suddenly outgas.

Unlike lithium batteries, deep discharging does not pose a problem for the EDLC. And while overcharging significantly reduces the service life, it is non-critical in terms of safety.

A possible short circuit presents an additional hazard potential when the EDLC is used in electric circuits. Due to the low serial internal resistance, high short-circuit currents can flow in this case even in relatively small designs. Consequently, it is important to use appropriate protective elements to interrupt the faulty circuit.

This also applies to every other type of accumulator that can dissipate a high amount of power within a short time. From our perspective, EDLCs are extremely safe and unproblematic overall.

EDLCs are therefore much more robust in comparison to lithium-ion batteries. What is the situation with service life? And how is it calculated?

Bodach: Experience from our projects shows that the service life depends to a great extent on the target application. With the help of cycle tests at a large number of different EDLCs, we have succeeded in creating a mathematical model based on the Law of Arrhenius, which enables us to estimate the service life quite accurately. In this context, the target application is important. This can be clarified by two diametrically opposed applications.

The use in an uninterruptible power supply (UPS) on the one hand and the use of the EDLC in a kinetic energy recovery system (KERS) on the other. Whereas the EDLC in the UPS remains in continuous trickle-charging mode and only rarely needs to supply energy to the system to be supported, it is permanently cycled in the KERS.

The decisive factors here are the parameters regarding the voltage, the current, the temperature and - last but not least - the supplier. In this case, an application-specific, scientifically supported evaluation of use is generally recommended.

Have your test series revealed major differences in the chemical composition from one manufacturer to another?

Bodach: In the past, there has been little fluctuation from lot to lot with brand manufacturers, and the specifications have matched our own measurement results. What market leaders like Maxwell or Nesscap specify on their data sheets is mostly reproducible. With 'no-name' caps from some manufacturers there certainly have been deviations in the past. They have got less with the newer elements, and one can see that things are improving, but the brand manufacturers still have an edge on them.

Do temperature cycles have a decisive influence over the service life, or are there other important factors?

Bodach: The average temperature for the duration of use of an EDLC carries approximately the same weighting as the average voltage. The average current is of subordinate importance in this case. Temperature and voltage are therefore the driving parameters since they favor the degradation of the electrolyte.

Does that mean that you assume the average temperature for the service life duration when calculating the service life, or do you have defined temperature profiles that reflect the temperatures at which the cap is used or loaded? Do the calculations incorporate individual parameters for the respective cell from the supplier?

Bodach: That depends on the application: In a wind turbine, for example, you can assume the mean annual temperature at the operating location in the immediate vicinity of the EDLC cells. Naturally, the parameters from the supplier are also included.

Is there a predictive algorithm that could be made available to customers or projects?

Bodach: That is possible in principle. We conduct application-specific, time-lapsed endurance tests that enable us to estimate the corresponding parameters correctly. The parameters also vary depending on the supplier. After 10,000 to 50,000 cycles, a relatively good forecast is possible in most cases. The results have also been confirmed by previous projects, where the accumulator systems developed performed in service as we predicted they would.

What can one say about balancing with respect to EDLCs?

Bodach: In our experience gained from trials and projects, balancing is needed when the storage unit is operated for a very long time with high float voltages such as is the case with a UPS. In that case, balancing with relatively low currents is the interesting aspect. It is different with recuperation systems: There, the capacitors are subjected to high loads and high equalizing currents are needed for effective balancing. The electronic balancing systems are often unable to deliver this, and they also cause high losses for the overall storage system.

In such cases it makes more sense to use one cell more, to size the capacitors for lower voltages and thereby increase their service life.

Does one need balancing for certain applications such as hybrid energy storage devices?

Bodach: From the application point of view, the same applies as mentioned before. In hybrid storage systems, the EDLC has to buffer the peak load. Generally, that means that balancing is not a critical matter for the EDLC part. On the other hand, the slow storage unit (LiIon) should certainly be provided with a BMS.

Many established manufacturers are only just beginning the transition to EDLC production. They are experimenting with different chemicals and compositions to find a way to differentiate themselves from the competition and develop systems for specific application areas. Lithium-ion-EDLC hybrid systems are a prominent example of this. How do you see the risks and pitfalls of such combined technologies?

Bodach: A classic EDLC stores energy in the Helmholtz layer, so it is a purely electrostatic storage medium. In contrast, a lithium cap also uses a chemical reaction to store the energy, so it needs to be judged on a quite different basis compared with an EDLC. The application has to be dimensioned differently. Basically, the lithium cap is a highly interesting component. I can see potential for it especially in energy harvesting, where the very small amount of self-discharge plays a role. However, attention needs to be paid to the fact that a lithium cap will probably be treated in the same way as a conventional battery in the Batteries Act (BattG), and that means the manufacturer has to be prepared to take it back.

The market's attitude towards EDLCs remains cautious, although production projects in the area of electromobility are already under way. What specific markets could mean the breakthrough into the mass market for EDLCs?

Bodach: The area of UPS would be the ideal field of application for EDLCs. In Germany, 95 percent of the already extremely rare mains failures last for less than one second, while 98 percent of mains failures are shorter than ten seconds. This can be covered perfectly with a short-term UPS. This market is ideal for EDLCs. At this point, the higher service life of the EDLCs is beneficial. This system has already proven itself in the area of energy storage in relation to the pitch adjustment in wind turbines. The toys market would also be hugely interesting as an ideal area of application.

Why is that?

Bodach: Imagine a remote-controlled model car that has been powered by rechargeable batteries that allow 45 minutes of fun between charging periods of up to two hours (before the fun can go on) - and now it is converted to EDLCs: Kids could charge their toys in a few minutes for about the same amount of playing time, and never have to change the 'battery'. We have already developed such models. Of course, at the moment the toy is a little more expensive, but that pays off for the user (and the environment) fast. The toy manufacturers need to be won over.

What else is preventing the market breakthrough of EDLCs? Where do you need to direct your persuasive efforts?

Bodach: The price, the delivery times and sometimes the minimum purchase quantities are currently a problem. If a developer sees a demand for half a million cells for his application, the price per cell would of course be adjusted downward accordingly. I believe that one must consistently continue to clarify and clearly address applications, and offer examples of projects that were realized with EDLCs. We need to highlight where and with which parameters it makes sense to use an EDLC. We have had very positive experience with Rutronik, which offered us opportunities as a university to test the latest EDLCs. This was very important. It takes lighthouse projects that show the capabilities of EDLCs - which will then also convince industry and result in more companies wanting to implement these types of accumulator concepts.

How could the maker scene help to move things along?

Bodach: I have a do-it-yourself enthusiast in my research team who runs an electric toothbrush on EDLCs that are charged using photovoltaic power. He also runs his computer mouse on an EDLC. That's an intriguing idea! A distributor such as Rutronik could provide maker groups with starter kits containing a small set of relatively cheap cells in order to get EDLCs into circulation. The same applies to schools: We have found that physics teachers are very interested in this component. Together with a short safety training course one could encourage pupils to experiment. That would make lessons more interesting, and hopefully it would help to increase the number of MINT students. Especially a degree in electrical engineering would guarantee a job for many young people.

What could cooperation projects with industrial customers look like?

Bodach: Precisely the same as our cooperation with Rutronik: A company knows what it wants, but may not yet have any idea how to implement what it wants. This is where we at the Faculty of Electrical Engineering at the University of Applied Sciences Zwickau can act as highly qualified contact partners who can develop this idea further. We have supported many of these types of projects in the past. A simple inquiry as to whether a joint project is possible is all it takes. Depending on how intensive the workload is, it may be possible for a student (internship, student research project, diploma thesis, or master thesis) to provide support and create a recommendation guideline for the next steps. The next steps would be a cooperation project, for example, for which the company provides financial support in the context of contract research. Really large projects involving high levels of scientific risk can also consider applying for state subsidies.

Are you currently working on externally-funded projects that you can tell us about?

Bodach: The largest project at the moment is WindNODE and involves approximately 70 project partners. The project coordinator is the grid operator 50Hertz. We are cooperating here with well-known project partners. From our perspective, electrical energy accumulators are also an exciting prospect here. Those who want to know more can find detailed and comprehensive information at www.windnode.de.

Why should a company decide to use EDLCs?

Bodach: The developers at the company should conduct tests and see the advantages for themselves. I have found the component to be extremely interesting for quite some time now. When used in the right location and with the right electrical system, EDLCs can revolutionize the energy accumulator world! The technology contained in EDLCs is cheap, and there is no danger of the raw materials required to manufacture them becoming scarce.

New XP Product Series

|

Nesscap Part Number |

Rutronik No. |

Capacitance Rating |

Biased Humidity Life* |

|

ESHSR-0003C0-2R7UC |

KUK974 |

2.7V 3F |

2,000 Hrs |

|

ESHSR-0005C0-2R7UC |

KUK973 |

2.7V 5F |

2,000 Hrs |

|

ESHSR-0006C0-2R7UC |

KUK972 |

2.7V 6F |

2,000 Hrs |

|

ESHSR-0010C0-2R7UC |

KUK971 |

2.7V 10F |

2,500 Hrs |

|

ESHSR-0025C0-2R7UC |

KUK965 |

2.7V 25F |

3,000 Hrs |

|

ESHSR-0050C0-2R7UC |

KUK970 |

2.7V 50F |

3,000 Hrs |

Standard Product Series

|

Nesscap Part Number |

Rutronik No. |

Capacitance Rating |

Biased Humidity Life* |

|

ESHSR-0003C0-2R7 |

KUK568 |

2.7V 3F |

< 500 Hrs |

|

ESHSR-0005C0-2R7 |

KUK798 |

2.7V 5F |

500 Hrs |

|

ESHSR-0006C0-2R7 |

KUK819 |

2.7V 6F |

< 500 Hrs |

|

ESHSR-0010C0-2R7 |

KUK638 |

2.7V 10F |

500 Hrs |

|

ESHSR-0025C0-2R7 |

KUK412 |

2.7V 25F |

500 Hrs |

|

ESHSR-0050C0-2R7 |

KUK443 |

2.7V 50F |

1,000 Hrs |

What is Special about Nesscap’s XP Series?

Durable and top-performing even under adverse conditions: Nesscap's new XP™ series has been specially engineered for use in conditions of high humidity and high temperatures.

Nesscap's new series has been subjected to the special 'Biased Humidity Test' conditions (2.7V, 90% relative humidity, 60°C) and proved itself with a significantly longer service life under direct current conditions in comparison with standard cells.

XP™ products are offered at capacitances ranging from 3F to 50F with dimensions and electrical specifications identical to those of Nesscap's corresponding standard cells. The XP™ series features patented closure and contact technology. All products have been extensively tested to ensure adherence to strict performance standards and are compliant with RoHS, UL and REACH. The XP™-series is rated for temperatures between -40°C and +65°C and provides a long cycle stability for at least 500,000 charging / discharging cycles.

Nesscap Ultracapacitors – What is Special about the Company?

Since being established in 1999, Nesscap has become an award winning global leader in technology innovation and product development of ultracapacitors. Nesscap Energy is a world leader in EDLC technology, with a broad range of standard commercial products including single cells and modules with varying voltage ranges. The company is ISO and TS certified and is focused on delivering exceptional quality.

Nesscap products are found in the market segments which provide diverse applications and global opportunities for continued growth: mobility, renewable energy, industrial, consumer and automotive. Nesscap products are used to replace the performance of energy and power needs for modern applications ranging from portable electronic devices to high-tech 'green' cars. They are available both as single cells as well as modules.

The properties of ultracapacitors are such that the technology can be used in areas of application where normal batteries are only of limited use with regard to performance, service lifetime and environmental conditions.

Nesscap continues active research and development programs to expand its current product portfolio. The product range includes single cells ranging from 3F to 360F as well as small modules with 5 V. Thanks to Nesscap's continued innovation and development, over 20 new products have been launched onto the market in the last five years.

Leave Us a Message