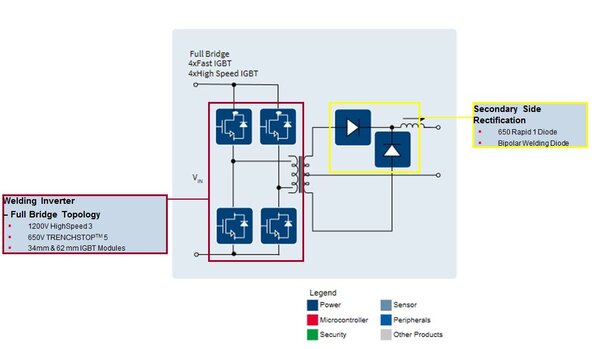

Infineon’s Leading Technology in Welding Applications

High Switching Frequency and Reduction of Turn-off Losses

Leading technologies are the key factor for being successful in the highly competitive welding market. Today, customers are requesting both budget-friendly and efficient solutions delivering high performance.

Infineon takes this challenge and offers a wide range of high-quality semiconductor solutions - from Discrete IGBTs for portable welders to Bipolar Diodes for highly efficient professional welders. Whereas high switching frequency and reduction of turn-off losses is one of the most important trends for the portable low cost welder market the reliability and the power density pointed out as main criterion in the heavy-industry.

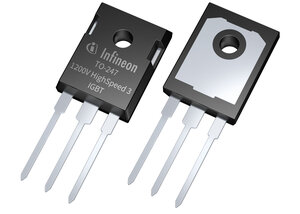

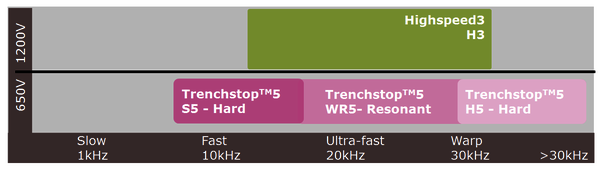

Discrete IGBTs

Meeting demands for the portable welders in terms of switching and conduction losses, our TRENCHSTOPTM 5 effects best performance compared to other IGBT on the market for one-phase inverters. Dependent on the switching behavior you can chose between different options. For three-phase welding Infineon recommends the 1200V High Speed3. Typical applications can be found in hobbyists in building constructions, workshops, car repair shops.

EiceDRIVER™ Compact

As every switch needs a driver, Infineon offers a broad range of dedicated drivers for Welding applications. We outline here one of our high voltage, high speed IGBT drivers with Coreless Transformers technology, EiceDRIVER™ Compact 1EDI20I12AF.

IGBT Modules

If your application requires a higher welding current, we recommend our well-known 62mm 1200V dual IGBT modules with the IGBT2 fast technology for high frequency switching. Our 62mm & 34 mm portfolio stands for flexibility, optimal electrical performance and for highest reliability. Typical applications these IGBT modules can be found are iron industry as well as the Industrial Automation.

Diodes

Depending on the particular welding market, Infineon offers different diodes as secondary side rectification:

The Rapid 1 power silicon diodes fill the gap between the SiC diodes and emitter-controlled diodes for up to 80A/650V.

The housing less welding diode is a high reliable and robust device specifically for the requirements in the automotive and metallurgical welding applications up to 20kA/600V.