NLM0011 - First NFC Configuration IC with Integrated CLO

Solves LED Current Setting Challenges, and Increases LED Driver Market Value

LED Current Setting – the Challenge! NFC Programming – the Solution! The Way Towards Simplified and Harmonized Methods

Importance of Constant Current Sources

To illuminate a light-emitting diode (LED) at a certain brightness level, an electrical circuit - the LED driver - must ensure sufficient current supply. At the same time having to avoid that the flowing current exceeds the maximum rating what would cause overheating and potentially destroy the LED. Considering that the voltage drop across an LED is approximately constant over a wide range of operating current, the logical consequence of a small increase in applied voltage is a significant change in current. It is hence advisable to connect LEDs only to constant current sources.

NFC for Simplified LED Current Setting

So far, design and logistics complexity when matching the LED current setting has posed challenges to the integrators of LED drivers and modules. On the one hand, ISET is not freely configurable and adjustable and, on the other, ILED requirements vary by the product and by the vendor. Also, to be considered, the mainstream plug-in resistor current configuration method is labor-intensive and inflexible.

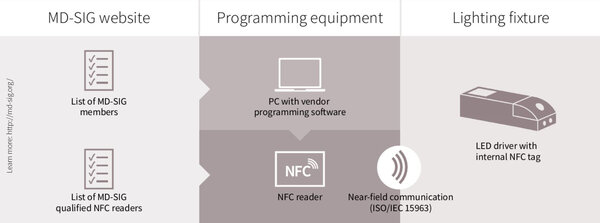

Now that the members of MD SIG (http://md-sig.org/), the global lighting-industry consortium, have successfully standardized a digital, wireless programming approach using near-field communication (NFC), likely, this method will soon be predominant. Simplified and harmonized methods are desired by manufacturers of LED luminaires to enable LED driver programming to set the operating characteristics on automated or manual production lines. The NFC system uses a programming device, commonly known as an NFC reader, which wirelessly transfers the programming data to an NFC tag inside the LED driver.

Digital, wireless programming approach using NFC as proposed by MD-SIG.

Benefits Throughout the LED Lighting Value Chain

LED-Driver Manufacturer

Reduction of the Total Cost of Ownership (TCO)

- reduce the number of product variants

- improve operational efficiency by eliminating the labor-intensive "plug-in resistor" current setting process step; programming happens during manufacturing without the need to connect to a power supply

- improved inventory turnover ratio

- enhanced flexibility and reduced logistics costs (adjusting the output current in the post-manufacturing process is possible)

Improvement of Product Innovation-grade and Quality

- a configurable product allows for more flexibility at the customers' end

- achieving a high level of output-current tolerance with in-production calibration

- safe configuration via a galvanic-isolated, contactless NFC interface

- having no more open connector for the plug-in resistor results in better protection from water

Luminaire Manufacturer

Reduction of the Total Cost of Ownership (TCO)

- fast current-matching process in the manufacturing line

- high flexibility in the LED module selection

- enhanced flexibility and reduced logistics costs (adjusting the output current in the post-manufacturing process is possible)

Improvement of Product Innovation-grade and Quality

- a configurable product allows for on-site brightness calibration increasing the flexibility for end-customers

- the precise output-current control ensures a high-quality light output

- decrease in logistics complexity due to the destination standard-based NFC configuration

- safe configuration via a galvanic-isolated, contactless NFC interface

End-User

- Upgraded product quality (lighting quality, uniformity)

- More flexibility due to on-site brightness calibration possibility (customer-defined brightness including individual room-by-room configuration)

Infineon’s NFC-PWM Series: Easy Implementation of LED-driver NFC Programming and CLO

Infineon responds to the developments in the industry by launching its NFC-PWM series. For now, it consists of the NLM0011 and the NLM0010 devices, two dual-mode NFC configuration ICs with pulse width modulation (PWM) output primarily designed for LED applications to enable NFC programming.

The NLM0011 is the first NFC configuration IC on the market with an integrated constant lumen output (CLO) function.

Both ICs come with advanced features such as operating-time counting, and on/off counting. For the customer, there is no need to invest extra efforts to enable these, neither to develop firmware nor to integrate a microcontroller. Adaptation to existing designs is easy.

Operation modes

The NLM0011 operates in two modes: configuration mode (passive) and lighting mode (active)

- In configuration mode, where the LED driver is not powered (no VCC applied to the NFC IC), the NFC IC is powered by the RF field sent from the NFC reader. Parameters stored in the non-volatile memory (NVM) can be configured wirelessly via the NFC interface.

- In lighting mode, as soon as the LED driver is under power (VCC applied to the NFC IC), a PWM output is generated according to the stored PWM parameters. During the active mode, the NFC interface is disabled.

PWM Parameters

The products in Infineon's NFC-PWM series generate a PWM signal with a fixed amplitude at 2.8 V. Thanks to the integrated voltage regulator (LDO), the level and the stability of the external supply voltage do not influence that. The adjustment of the DC-voltage level is achieved by modifying the PWM duty cycle. The signal output is produced by an internal clock, derived from an internal oscillator running at a frequency of 27.12 MHz. The duty-cycle accuracy is better than 0.1 percent. The PWM resolution depends on the selected PWM frequency: 15 bit @ 1 kHz or 10 bit @ 30 kHz.

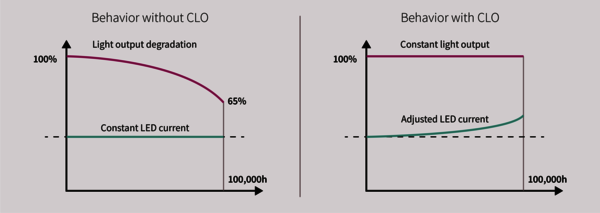

CLO Implementation

The CLO is a quasi-control system (self-regulating system) that fights the natural degradation of an LED's light output. This technology maintains the luminous flux constant by regulating the LED current over the life of an LED.

The NLM0011 has an integrated operation time counter (OTC), which automatically records the accumulated operation time. An integrated 8-point CLO table stores the degradation curve of the LED module. The LED luminaire manufacturers program this curve according to the LED selection. As soon as the CLO table is programmed, the duty cycle of the PWM signal is then automatically adjusted to compensate for the LED degradation. The actual duty cycle, as a function of the actual operating time, is calculated by linear interpolation between two neighbored reference points. The NLM0011 is continuously counting the operation time and is continuously interpolating the duty-cycle correction factor, which is then multiplied with the nominal duty-cycle value to get the actual duty-cycle value.

Highlight Products, Specifications and Special Features

Specifications:

- NFC contactless interface based on ISO/IEC 15963 standard

- 1x PWM output with fixed amplitude at 2.8 V, and configurable duty cycle between 0 % and 100 %

- Non-volatile memory (NVM) including UID and 20 bytes free memory for user data

- Constant lumen output (CLO) with 8 configurable reference points

- On/off counting and integrated operation-time counter (OTC)

Special Features:

- First NFC configuration IC in the market with build-in CLO and on/off counting functions

- Highly stable PWM output with fixed 2.8 V amplitude and ±0.1 % duty-cycle accuracy

- Internal voltage regulator (LDO) to avoid the influence of unstable voltage supply

- Effortless integration into existing designs to replace the “plug-in resistor” current-configuration concept

- Compatible with the MD-SIG "NFC Programming Specification" and verified with MD-SIG certified NFC readers

Difference to NLM0011:

- Light version -> without the CLO function

- All other features equal the ones of NLM0011

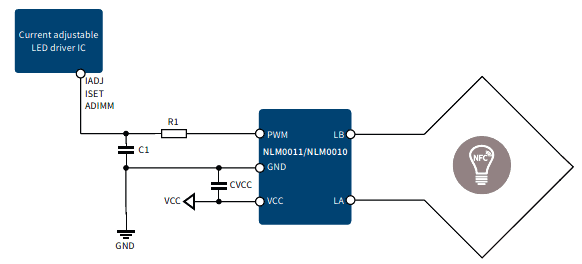

System diagram: LED lighting – wireless NFC-interface design in LED drivers using NLM0011 / NLM0010.

Evaluation Kit: For Development, Thorough Testing and Evaluation

Image & Downloads

Name and Key Components

Description and Target Applications

Key Features and Benefits

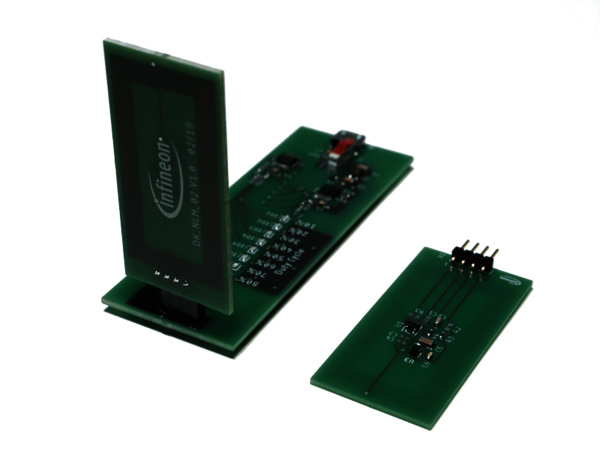

EVAL_NLM0011_DC

OPN: EVALNLM0011DCTOBO1

Evaluation Kit Contains:

- NFC board 3 to 5 V (DK_NLM_02)

- NFC board 5 to 25 V (DK_NLM_01)

- Demo board (DK_NLM_03) exchangeable with customer board

- For most up-to-date tech materials use Infineon's EXCLUSIVE ACCESS download service

- USB cable (A to micro B)

Infineon Component:

- Dual-mode NFC wireless configuration IC (NLM0011)

Fast demonstration of NLM0011 features: parameter setting, configuration and measurement of PWM signal can be done via a smartphone and the provided mobile app, without additional hardware. Quick parameter setting covers: PWM frequency, PWM duty cycle, operating hours, on/off count, CLO table. Development of application software for NFC readers without full system use.

Targeting: LED lighting applications

Features:

- NFC antenna for programming or reading the EEPROM of NLM0011 in passive mode

- Low-pass filter (optional) for smoothing the pulsed voltage

- LDO for adjusting the input voltage to 5 V

- 4-pol connector for connecting the demo or customer board incl. VCC, GND, PWM and PWM filtered

Benefits:

- Fast demonstration and evaluation via smartphone and provided mobile app

- No additional hardware needed for demonstration and evaluation purposes, and no full system for application software developmen

- Demo board exchangeable with customer board allowing to test the NLM0011 directly on the customer's board

- Two NFC boards (3-5 V and 5-25 V) are supplied to respond to differences in VCC

- By registering the kit for EXCLUSIVE ACCESS customers are granted rights to download high quality, most up-to-date tech materials not available elsewhere incl. "stay informed" function alerting in case of changes of or new additions to the package

Contact Us