Upcoming Webinar

LEV Chargers: How Infineon Products Enable Green Mobility

This webinar gives an overview about LEV (Light Electric Vehicle) market with special focus on LEV chargers. The charger application and use topologies for different power ranges, starting from low power chargers for e-bikes up to high power forklift chargers will be described and mapped to suitable Infineon switches, diodes and drivers.

Overview

The LEV application, together with a market overview, market drivers and application trends are introduced in this presentation. Infineon Technologies offers a wide range of products for the LEV charger, motor control and battery management. While the Infineon offerings for motor control and battery management will be mentioned, the main focus of the presentation is on the LEV battery charger. Solutions and use topologies for different power classes of chargers will be described. Starting from below 200W and reaching up to 2kW and above, covering applications ranging from e-bikes, e-scooters and e-3 wheelers up to micro e-cars. Suitable CoolMOS™ switches and their benefits in the described charger solutions will be presented, together with the suitable CoolSiC™ diodes and EiceDRIVER™ gate driver ICs. Furthermore a 2kW high efficient natural convection cooled demonstrator design based on CoolMOSTM P7 will be presented which can be used for charging 48V lead-acid and Li-ion batteries.

Key Takeaways

- Gain insight through an LEV market overview

- Learn about the range of LEV battery charger applications for different power ranges

- Understand the range of Infineon solutions for low, mid, and high power battery charger

- Be introduced to Infineon demonstrator: 2kW high efficient natural convection cooled battery charger

Date: September 17, 2019

Time: 10 AM EDT (7 AM PDT / 4:00 PM CEST)

Duration: 1 hour

Presented by Infineon & Rutronik

Electrifying (the) Future

Fossil fuels and alarming emission levels? We can do better than that!

One out of many essential steps towards an energy-efficient world lies in growing the popularity - and consequently the use - of electrified two-, three- and four-wheel vehicles. New materials and technologies enable nowadays greater power efficiency, smaller size, lighter weight, and lower cost solutions. Consumers look for affordable, clean transportation alternatives to address congestion, poor air quality, and lack of mobility.

Want to play a key role in accelerating the transition to e-mobility with your products? Then turn to a true expert, a leader in power, sensing and security solutions: Infineon.

LEVs: an Increasingly Important EV Sub-Category

Three-hurdles Slowing Mass Deployment

When focusing on the mass deployment of all-electric vehicles and gasoline-electric hybrids the challenges currently recognized can be summarized in three main hurdles:

- The high initial investment,

- The limited charging infrastructure available,

- And consumer misperceptions about their operation.

In other words, battery system cost, battery density, range limitations and charging constraints continue to be impediments to the adoption.

The Rise of LEVs

The named obstacles have become a trigger for the evolvement of another segment in the EV market: light electric vehicles (LEVs). Compared with other EVs as well as with conventional gasoline-powered vehicles, they are extremely low-priced what makes them affordable even to the financially underprivileged! They can be charged from the grid (e.g. power plugs in private homes) and do not necessarily require installation of a specific charging infrastructure. And due to an extremely simple configuration both - their functioning and handling - are easy to understand. Targets are clearly those driving short distances at lower speed not holding a driving license as for LEVs no certification - neither for the vehicle, nor for the driver - is legally stipulated until today. Depending on the purpose of use there are variants with and without space for carry-on items. And most importantly, they fulfill the zero emissions mandate.

Currently, the LEV market in units is six to ten times larger than the one for plug-in EVs. Already in the near future, LEVs are expected to be highly integrated with automated vehicle technology, i.e. sensors. The industry has seen an incredibly fast rate of conversion from internal combustion engines to full electrical drives (e.g. approximately 62% of the number of forklift units sold in 2018 have already been electrical).

Complete System Solutions for LEVs

Infineon specializes in offering complete system solutions encompassing all fundamentals, namely power electronics, controllers, security, and authentication. And of course our advanced sensor technologies add value, too. With our pioneering spirit sustained by technical know-how, highest quality standards and preeminent manufacturing expertise throughout the entire supply chain we strive to be benchmark in addressing a broad range of light electrical vehicles. With our portfolio we already cater for e-skateboards, e-scooters, pedal electric cycles (i.e. pedelecs), low speed electric cars, e-forklifts, e-rickshaws, three-wheelers in general and many others. Multiple functional blocks are thereby considered (e.g. motor control, battery chargers, air conditioning systems, hydraulic control). Power management and consumption and voltage regulation are covered by an exceptional selection of power components (high voltage CoolMOS™, low voltage OptiMOS™, StrongIRFET™, SiC and GaN based products), XMC™ and AURIX™ microcontrollers, and EiceDRIVER™ gate driver ICs - amongst others. In other words, Infineon offers all components that are needed for the compact, cost-effective designs of today, and for the innovative vehicles of tomorrow.

Features and Benefits:

- Most robust silicon solutions in the market

- Ideal for both - low and high power density application

- Industry-leading performance with the best figure of merit (FOM) enabling rugged and reliable system designs with reduced BOM count and consequently at an attractive overall system cost level

- Enabling various levels of integration and space saving (depending on the application)

- Application based qualification procedure (beyond JEDEC) according to stringent industrial and automotive (if applicable) standards

- Perfect choice for multiple functional blocks in LEVs (e.g. battery charging, motor control, battery management system, etc.)

LEV Industry Characteristics

Infineon is aware of its customers' major challenges and the impactful characteristics of the LEV industry:

- strong price erosion what makes it a cost driven segment

- time-to-market pressure

- small form factors

- relaxed lifetime expectations

- growing demand for easy-to-use system level solutions (plug and play, turnkey) comprising the technology, soft- and hardware as well as services (e.g. software design) due to increasing system complexity

Why Infineon is the Right Partner for your LEV Projects

- Most reliable, industry-leading solutions, delivering either best-in-class performance or price competitive (cost-optimized) solutions for the widest range of LEV applications

- Mastering all leading power technologies (Si, SiC, GaN)

- Most comprehensive packaging portfolio in Si MOSFET technologies (THT, SMD)

- Number one in in the low voltage MOSFET market

- Extensive application system understanding and manufacturing expertise throughout the entire supply chain

- High quality volume supply that results in faster time to market

- Global application design support via a worldwide network of field application engineers and trusted distributors

- Broad portfolio - all out of one expert's hand

- Line-up for ease-of-use: combination of complementary switches, gate driver ICs, and controllers

Our Service is Your Success in the Highly Competitive LEV Industry

|

Critical success factors |

Infineon’s offering |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Low Power Light Electric Vehicles (Power Level: 1kW - 10kW; Value Drivers: System Cost, Power Density)

Low Power LEVs can be separated from the rest of higher power LEVs by the following characteristics:

- power level: 1kW - 10kW

- voltage range: 24V - 72V

- two- and three-wheelers

- main purpose: short distance passenger transport

- value drivers: system cost, power density

Target Applications:

- E-scooters (standing / self-balancing and folding types)

- E-bikes

- E-three-wheelers

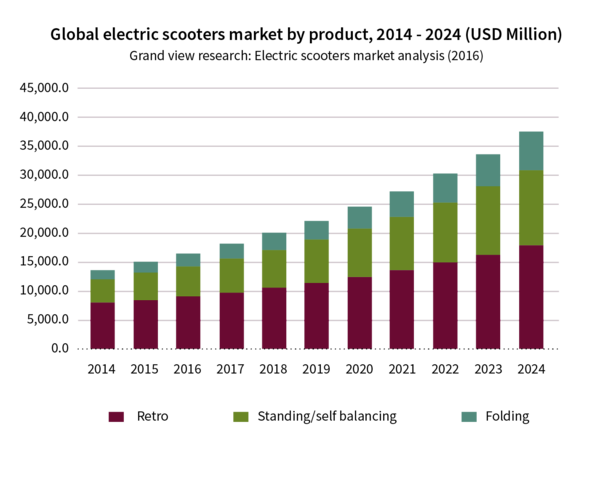

In contrast to the relatively small volumes of EVs, millions of electrified two-wheelers have already been sold worldwide. The environmentally friendly vehicles offer a very high degree of mobility combined with convenience and other fun factors. All that at much lower initial and operational costs compared to a typical EV. Emission-free driving versus congested city traffic - governments around the globe are alerted that it is time for greener politics in favor of light e-mobility (e.g. supporting innovative concepts such as dockless e-scooter sharing services or downtown traffic area accessible only via e-two-wheelers).

Top Performance versus Cost Optimization

When it comes to high volume production, the range and speed of low power LEV applications are distinguishing factors. No matter if customers work on designs with either top performance targets or rather concentrate on cost optimization, Infineon is prepared to deliver the products they require. With best-in-class solutions for motor control, our customers are maximizing levels of space and/or volume savings (e.g. essential for two-wheelers). StrongIRFET™ MOSFETs, to the contrary, are to be chosen for the development of cost optimized solutions whenever space and weight do not form limiting parameters (e.g. for three-wheelers).

Electrical Two-Wheelers – Skyrocketing Sales Worldwide

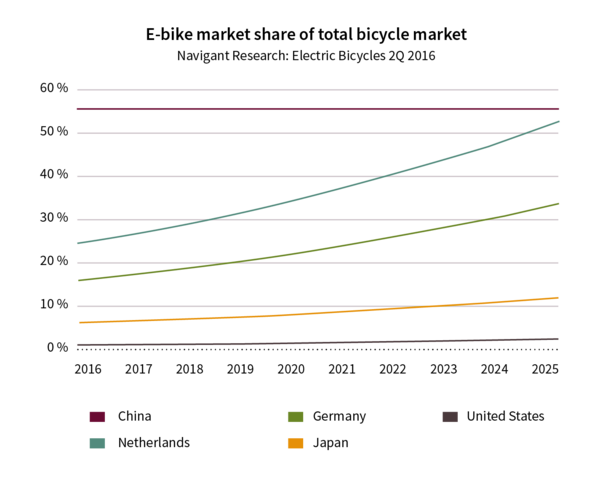

Even industry insight professionals did not anticipate the speed at which the Western European e-bike market has been growing over the past years. The share of e-bikes of the total bicycle market has become substantial - and is expected to rise up to 30-40 % in many countries. Instead of being a specialty recreational device as it was a couple of years ago e-bikes in Europe are evolving to a standard bicycle product, especially for work commuters who do not want to show up to work sweating all over. The popularity of these two-wheelers has grown with the significant reduction of weight and some variants are even foldable. Another influencing factor has been the price drop due to the lower cost of lithium ion batteries which are more and more replacing the former standard being lead acid ones. The switch in battery type does also open up new markets in countries where the saturation level had already been reached. With the lithium technology batteries are getting smaller and higher voltages are possible. Last but not least, people are more prone to replace a car with an e-bike than with a regular bicycle.

Fluctuating fuel prices have led to a decrease in the sales of fuel-powered vehicles and continue spurring sales of e-scooters (two- and three-wheeled). The latter are also supported by government subsidies in European and Asian regions. Moreover, OEMs enhancing their product portfolios are fostering global market growth. Same as for e-bikes, declining battery costs will have a positive effect on opportunities for market players. And not to forget about increasing product demand as consequence of introducing more and more e-scooter sharing services - one of many aspects of the sustainable urban mobility trend.

At this moment in time there are only two dissuasive concerns users have: slow charging time and limited range. Manufacturers are intensively working on solutions to overcome any existing barriers of adoption of e-scooters. Different battery technologies, solar power, battery swapping stations plus the development of a supercharger network are only few examples - anything that provides more convenience to the consumer.

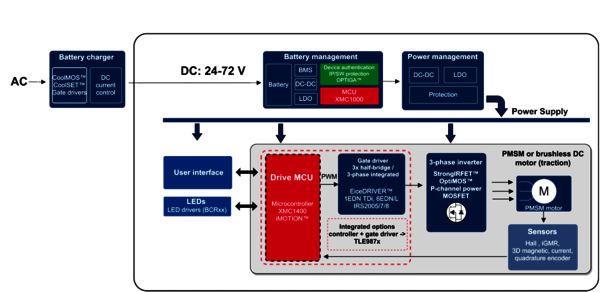

iMOTION™ - Digital motor Control for E-bikes and E-scooters (See also Recommended Products)

One particular set of products suitable for low power two-wheelers such as e-bikes and folding e-scooters are Infineon's iMOTION™ motor control ICs. Integrated into these ICs are all the control and analog interface functions required for sensor-less, field-oriented control (FOC) of PM motors using DC link or leg shunt current measurements. In addition, they feature Infineon's patented and field-proven motor control engine (MCE) that eliminates software coding from the motor control algorithm development process. Implementing a variable speed drive is reduced to configuring the MCE for the respective motor. Assisted by powerful tools like MCEWizard and MCEDesigner it is possible to have the motor up and running in less than an hour. By comprising both, the required hardware and software to perform sensor-less control of a permanent magnet synchronous motor (PMSM), iMOTION™ ICs provide the highest energy efficient motor system with the lowest system cost for the named applications.

Recommended Highlight Products

Motor Control

IRFS3006TRL7PP

D2PAK (TO-263) 7pin, single N-channel HEXFET® power MOSFET, 60V and RDS(on), max = 2.1mΩ

Performance & cost optimized

MOSFET

IPT007N06N

TO-leadless, single N-channel OptiMOSTM power MOSFET, 60V and RDS(on), max = 0.7mΩ

Best in class

MOSFET

BSC039N06NS

PQFN 5x6mm, single N-channel OptiMOSTM power MOSFET, 60V and RDS(on), max = 3.9mΩ

Cost optimized

Particularly suitable for e-scooters

MOSFET

IRFH7545TRPBF

PQFN 5x6mm, single N-channel HEXFET® power MOSFET, 60V and RDS(on), max = 5.2mΩ

Cost optimized

Particularly suitable for e-bikes and e-scooters

MOSFET

IRFB3607PBF

TO-220AB, single N-channel HEXFET® power MOSFET, 75V and RDS(on), max = 9.0mΩ

Cost optimized

Particularly suitable for e-bikes and e-scooters

MOSFET

IPT029N08N5

TO-leadless, single N-channel OptiMOSTM 5 power MOSFET, 80V and RDS(on), max = 2.9mΩ

Best in class technology

MOSFET

IPP052N08N5

TO-220, single N-channel OptiMOSTM 5 power MOSFET, 80V and

RDS(on), max = 5.2mΩ

Cost optimized

MOSFET

IPT029N08N5

TO-leadless, single N-channel OptiMOSTM 5 power MOSFET, 80V and RDS(on), max = 2.9mΩ

Best in class technology

MOSFET

IPB017N10N5

D2PAK (TO-263) 7pin, single N-channel OptiMOSTM 5 power MOSFET, 100 V and RDS(on), max =

1.7 mΩ

Performance & cost optimized

MOSFET

IPB042N10N3

D2PAK (TO-263), single N-channel OptiMOSTM 3 power MOSFET, 100 V and RDS(on), max = 4.2 mΩ

Cost optimized

MOSFET

IPB048N15N5

D2PAK (TO-263), single N-channel OptiMOSTM 5 power MOSFET, 150 V and RDS(on), max = 4.8 mΩ

Cost optimized

MOSFET

IRFP4668PBF

IRFP4668PBF

TO-247AC, single N-channel HEXFET® power MOSFET, 200 V and RDS(on), max = 9.7 mΩ

Cost optimized

MOSFET

IR2136STRPBF

600 V three-phase gate driver IC for IGBTs and MOSFETs with typical

0.2 A source and 0.35 A sink current w/ over-current shutdown

Gate Driver IC

IRS2008SPBF

200 V half-bridge gate driver IC with shutdown input, typical 0.29 A source and 0.6 A sink currents

Gate Driver IC

2EDL05N06PF

EiceDRIVER™ Compact, 600 V half-bridge gate driver IC with typical 0.36 A source and 0.7 A sink output currents

Particularly suitable for e-scooters

Gate Driver IC

6EDL04N02PR

EiceDRIVER™ Compact, full bridge three-phase gate driver IC with thin-film-SOI-technology

• No cross-conduction

• Detection of over current and under voltage supply

Particularly suitable for e-bikes and e-scooters

Gate Driver IC

1EDN7550

EiceDRIVER™ fast 1-channel low-side 4/8 A gate driver IC

• Robust against false MOSFET triggering

• Highest effective MOSFET driving power

• Increased power density and BOM savings

Gate Driver IC

TLE9877QXW40

3-Phase Bridge Driver IC with Integrated ARM® Cortex® M3

• High system reliability

• Increased power density and BOM savings

• Reduced development time

Micro-

controller

XMC1403-Q064X0200 AA

32-bit Microcontrollers with ARM® Cortex®-M0, focus on low-cost embedded control applications

- Easy 3-phase inverter implementation with a single CCU8 PWM unit, offering shadow register transfer, external input for fault control, binary and floating pre-scaler, 16-bit to 64-bit width

- POSIF interface to directly connect hall sensors and incremental encoder.

- 12-bit ADC with on-chip adjustable gain of x1, x3, x6 or x12

Microcontroller

IMC101T-F064

iMOTION™ digital motor controller, highly integrated solution

• All digital and analog components integrated

• Next generation of Motion Control Engine (MCE 2.0)

• Integrated protection features

Particularly suitable for e-bikes and e-scooters

Motor Control IC

IFX21004TN

Monolithically integrated w/ dual output: 5 V and 15 V

• Very low current consumption

• Thermal optimized package

Voltage regulator

Hall Switch (TLE4964-1M)

Integrated Hall effect switch, 3.0 V to 32 V operating supply voltage

• Operation from unregulated power supply

• Reverse polarity protection (-18 V)

Sensor

IMC101T-F064

iMOTION™ digital motor controller, highly integrated solution

• All digital and analog components integrated

• Next generation of Motion Control Engine (MCE 2.0)

• Integrated protection features

Particularly suitable for e-bikes and e-scooters

Motor Control IC

3D Hall Sensor (TLE493DW2B6Ax)

3D magnetic sensor, flux density sensing of ±160 mT

• Diagnostic measurements

• Power down mode with 7 nA (typ)

Sensor

Protection

IPB017N10N5LF

D2PAK (TO-263) 7pin, single N-channel OptiMOSTM 5 LinearFET, 100 V and RDS(on), max = 1.7 mΩ

Revolutionary product for hot-swap & e-fuse

MOSFET

OPTIGA™ Trust B SLE95250

Security / authentication IC for battery packs

• Easy integration thanks to full turnkey design

Particularly suitable for e-bikes and e-scooters

Security Chip

Battery Chargers for Light Electric Vehicles (Charging Applications from 200 W to More than 5 kW)

Off-Board versus On-Board Battery Chargers

Depending on their power requirements, LEV batteries can be charged either directly from the grid (i.e. any standard wall outlet) through a dedicated on-board charger or through the use of a low cost off-board charger.

Off-board chargers are more suitable if:

- The LEV can be easily located / moved close to the charger (even with an empty battery!) (i.e. e-bikes, folding e-scooters)

- The LEV battery does not require a complex battery management system, e.g. low cost sealed lead acid (SLA) batteries (i.e. low cost scooters, electrical wheelchairs

- Whenever charging requires very high power, because of limitations of weight/volume on the vehicle itself - as is the case for electrical forklifts

AC on-board chargers are more suitable if:

- More flexibility in charging is needed (no special infrastructure has to be installed, no need to carry additional charging equipment) (i.e. low speed EVs (quadricycles), golf carts, small electric lift trucks)

- More complex battery management systems are used, e.g. for Lithium ion batteries (i.e. high power e-scooters)

The on-board charger's performance is evaluated by its power-conversion efficiency and power quality (i.e. total harmonic distortion and power factor). As for all items installed in the vehicle, size (the smaller, the better), weight (the lighter, the better), and lifetime (the longer, the better) are critical parameters. Conventional on-board chargers usually have a two-stage structure consisting of a power factor correction (PFC) stage and a DC-DC power-conversion stage. This specific structure brings along major drawbacks such as low efficiency and circuit complexity, and a bulky intermediate DC link capacitor. Due to high current flowing through the intermediate DC link capacitor significant power loss is caused, what considerably reduces the capacitor lifetime, eventually leading to capacitor failure. As an alternative to the two-stage structure single-stage approaches are being investigated with the aim to eliminate the PFC stage and reduce the DC link capacitance.

Energy Efficiency – Critical Factor with Further Pick-up in Sales

At this moment, the battery charger market for LEVs is mostly cost driven, as the majority of LEVs sold today are low cost two- and three-wheelers. However, considering that the number of LEVs is expected to grow further, the efficiency becomes particularly important. Especially in countries with weaker power grids every percentage point of efficiency increase translates into significant energy savings. A noteworthy relief of the national power networks!

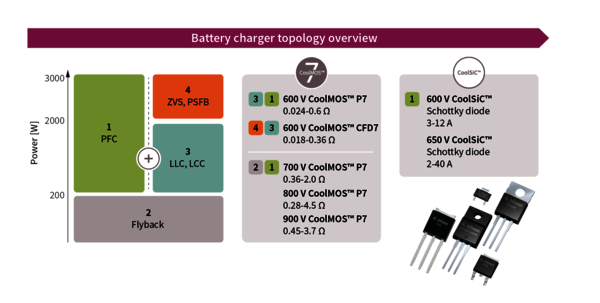

Infineon’s LEV Battery Charger Solutions

Infineon's LEV on-board and off-board battery charger solutions comprised of power MOSFETs, gate driver ICs, PWM/flyback controllers, integrated power stage ICs and microcontrollers are optimized to fit any system. In order to satisfy as many customer requirements as possible different topologies are available and meeting a variety of cost / performance optimization targets is possible.

Customers benefit from small form factors, best-in-class performance ratio (attractive pricing with competitive long term price down roadmap), easy-to-use technologies, powerful and reliable components.

OPTIGA™ Trust – Authentication at its Best (See also Recommended Products)

Another particular aspect of interest for chargers is their close connection with the type of battery stacks that they are supposed to charge. Practically, any LEV manufacturer selects different variants of batteries that best fit its own, very specific applications. The battery chargers must hence be designed with the proper charging algorithms for the corresponding battery stacks chosen by the LEV manufacturer. It is not advisable to connect any charger type to any battery! Otherwise there can be a significant risk of damaging the batteries, and void the manufacturer's warranty. Infineon's OPTIGA™ Trust security solution is easy to use and implement, and will ensure that only the right type of charger is used in connection with a certain type of battery, reducing the risk of hazardous damage/fires.

CoolMOS™ - Cutting-Edge Power MOSFET Technology (See also Recommended Products)

Our CoolMOS™ P7 offers the optimized balance between high efficiency and ease of use. Customers may choose from 71 parts in 9 different packages with an impressive RDS(on) granularity ranging from 24 mΩ to 600 mΩ. Industrial and standard grade packages are available.

Our CoolMOS™ CFD7 fulfills customer needs by providing efficiency improvements of up to 1.45 % compared to previous CoolMOS™ families and most similar competitive offerings. Its attractive price convinces with a competitive long term price down roadmap.

Recommended Highlight Products

Charger

IPW60R037P7

TO-247, 600 V CoolMOSTM P7 power transistor / Superjunction MOSFET, RDS(on), max = 37 mΩ

Best in class technology, highest power levels

MOSFET

IPW60R060P7

TO-247, 600 V CoolMOSTM P7 power transistor / Superjunction MOSFET, RDS(on), max = 60 mΩ

Performance and cost optimized

MOSFET

IPW60R080P7

TO-247, 600 V CoolMOSTM P7 power transistor / Superjunction MOSFET, RDS(on), max = 80 mΩ

Cost optimized up to 2.5 kW

Particularly suitable for e-scooters

MOSFET

IPW60R070CFD7

TO-247, 600 V CoolMOSTM CFD7 power transistor / high voltage Superjunction MOSFET with integrated ultrafast body diode, RDS(on), max = 70 mΩ

Cost optimized for resonant switching topologies

MOSFET

IPAW60R280P7S

TO-220 FullPAK wide creepage,

600 V CoolMOSTM P7 power transistor / Superjunction MOSFET, RDS(on), max = 280 mΩ

Cost optimized for flyback, low power chargers

Particularly suitable for e-bikes

MOSFET

IPA70R450P7S

TO-220 FullPAK, 700 V CoolMOSTM P7 power transistor / Superjunction MOSFET, RDS(on), max = 450 mΩ

Performance optimized, low power chargers with flyback topology

MOSFET

IPA80R360P7

TO-220 FullPAK, 800 V CoolMOSTM P7 power transistor / Superjunction MOSFET, RDS(on), max = 360 mΩ

Cost optimized, low power chargers with flyback topology

MOSFET

IPA95R450P7

TO-220 FullPAK, 950 V CoolMOSTM P7 power transistor / Superjunction MOSFET, RDS(on), max = 450 mΩ

Low power chargers with flyback topology

MOSFET

IDH16G65C6

TO-220 real 2pin, CoolSiC™ Schottky diode 650 V G6 for high power PFC topologies

Schottky Diode

IKB40N65ES5

D2PAK (TO-263), 650 V / 40 A, high speed switching TRENCHSTOP™ 5, addressing applications switching between 10 kHz and 40 kHz

• Optimized for high power chargers

• Co-packed with full rated current fast and soft anti-parallel diode

IGBT Discrete

IKB40N65EF5

D2PAK (TO-263), 650 V / 40 A, high speed switching TRENCHSTOP™ 5

• Optimized for compact, lower power chargers

• Co-packed with full rated current fast and soft anti-parallel diode

IGBT Discrete

2EDL05N06PF

EiceDRIVER™ Compact, 600 V half-bridge gate driver IC with typical 0.36 A source and 0.7 A sink output currents

Gate Driver IC

2EDN7524F

Fast dual-channel 5 A EiceDRIVER™ gate driver IC, peak source/sink current

• Fast and reliable MOSFET turn-off, independent of control IC

• Increased GND-bounce robustness

• Saves switching diodes

• Option to increase drive current by truly concurrent switching of 2 channels

Gate Driver IC

1EDN8550

Fast single-channel, low-side, non-isolated EiceDRIVER™ gate driver IC with 4 A source current/ 8 A sink current

• With truly differential inputs -> robust against false MOSFET triggering

• Highest effective MOSFET driving power

• Increased power density and BOM savings

Gate Driver IC

ICE2HS01G

High performance resonant mode controller designed especially for high efficiency half-bridge or full-bridge LLC resonant converter with synchronous rectification

Particularly suitable for e-bikes and e-scooters

AC-DC PWM-PFC Controller

ICE3PCS01G

14pin wide input range (85 VAC to 265 VAC ) controller IC for active CCM power factor correction converter

- Lowest internal reference trimmed at 2.5 V and integrated digital control voltage loop

- Low peak current limit at 0.2 V

- Adjustable gate switching frequency range from 21 kHz to 100 kHz

- Able to synchronize with external frequency range from 50 kHz to 100 kHz

- 95 % efficiency at full load for all input voltage ranges

Micro-Controller

ICE3PCS01G

14pin wide input range (85 VAC to 265 VAC ) controller IC for active CCM power factor correction converter

- Lowest internal reference trimmed at 2.5 V and integrated digital control voltage loop

- Low peak current limit at 0.2 V

- Adjustable gate switching frequency range from 21 kHz to 100 kHz

- Able to synchronize with external frequency range from 50 kHz to 100 kHz

- 95 % efficiency at full load for all input voltage ranges

Micro-Controller

ICE3PCS01G

14pin wide input range (85 VAC to 265 VAC ) controller IC for active CCM power factor correction converter

- Lowest internal reference trimmed at 2.5 V and integrated digital control voltage loop

- Low peak current limit at 0.2 V

- Adjustable gate switching frequency range from 21 kHz to 100 kHz

- Able to synchronize with external frequency range from 50 kHz to 100 kHz

- 95 % efficiency at full load for all input voltage ranges

Micro-Controller

XMC4300-F100K256

EtherCAT® node on an ARM® Cortex ®-M4 @ 144 MHz with on-chip flash and analog/mixed signal capabilities with outstanding Flash to RAM ratio

Cost & performance optimized main microcontroller for chargers

Particularly suitable for e-bikes and e-scooters

Micro-Controller

ICE5GR4780AG

Fixed frequency CoolSET™ G5, auxiliary power supply with 125 kHz maximum switching frequency and 800 V integrated MOSFET

• Power delivery of up to 15 W with universal wide input range

(85~300 VAC) DCM design

• Brown in protection, fast and robust start-up operation with cascode configuration

• Built-in digital soft-start

Particularly suitable for e-bikes and e-scooters

AC-DC integrated Power Stage

Development and Evaluation (Environment for Prototyping and Thorough Testing, Evaluation, Demonstration)

Development Tool:

DAVE™ - professional development platform for XMC™ microcontrollers

DAVE™ and complementary tools supporting the entire development process from evaluation-to-production (E2P). Experience DAVE™ IDE, XMC™ Lib (Low Level Driver), DAVE™ APPs and examples and reuse in one of the major ARM® compiler/IDEs such as Altium, Atollic, ARM/KEIL, IAR Systems, Rowley.

Recommended Demoboard Platform and Evaluation Board:

Low voltage drives scalable power demoboard platform (5 interchangeable boards) (for more details click here)

Image

Board Name and Key Components

Description and Target Applications

Key Features and Benefits

KIT_LGPWR_BOM003

Power half-bridge board featuring OptiMOS™ power MOSFETs

OPN: KITLGPWRBOM003TOBO1

Infineon components:

- OptiMOS™ 5 80 V power MOSFET (IPT012N08N5)

- OptiMOS™ 5 60 V TO-leadless n-channel power MOSFET (IPT007N06N)

- OptiMOS™ 5 100 V power MOSFET (IPB017N10N5)

- OptiMOS™ 5 150 V power MOSFET (IPB044N15N5)

- OptiMOS™ 3 200 V power MOSFET (IPB107N20N3G)

- OptiMOS™ 3 250 V power MOSFET (IPB200N25N3G)

The modular demonstration platform supports multi-phase topologies and variable half-bridge paralleling.

The power board demonstrates performance of Infineon's power MOSFET family OptiMOS™ in D2PAK, D2PAK-7 and TO-leadless packages, in terms of parallelization and thermal behavior.

Interchangeable Board Approach:

Infineon strongly recommends using this board with

- Master mother board (KIT_LGMB_BOM003)

- Mother board (KIT_LGMB_BOM503)

- Daughter board (KIT_LGDB_BOM003)

- Capacitor board (KIT_LGCAP_BOM003)

Target use / Applications:

Light electric vehicle (LEV) prototyping (Low speed electric vehicles, e-scooters, three-wheelers, golf carts, e-forklifts)

Features:

- IMS PBC for increased cooling

- Basic software with GUI

Benefits:

- Scalability and versatility

- Rapid prototyping

- Fast building of customized solutions

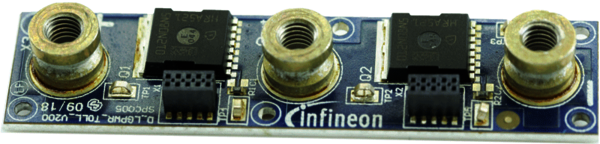

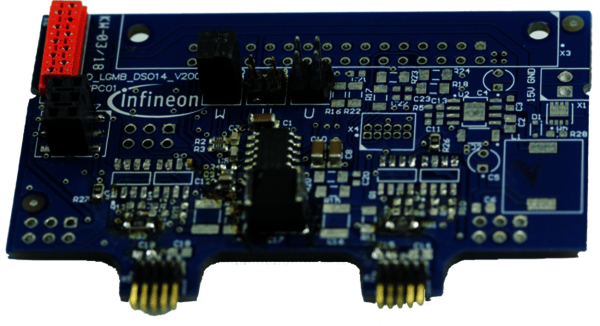

KIT_LGMB_BOM003

Master mother board featuring EiceDRIVER™ (2EDL23N06PJ) gate driver IC

OPN: KITLGMBBOM003TOBO1

Infineon components:

- EiceDRIVER™ 600 V half-bridge gate driver IC (2EDL23N06PJ)

- Voltage regulator (IFX91041EJV50)

- OptiMOS™ 3 30 V power MOSFET (BSZ086P03NS3 G)

The master mother board (KIT_LGMB_BOM003) including Infineon's EiceDRIVER™ half-bridge gate driver IC (2EDL23N06PJ) connects to the first power board (KIT_LGPWR_BOM003) and also provides supply for the XMC™ control card (Evaluation board KIT_XMC4400_DC_V1).

Interchangeable Board Approach:

Infineon strongly recommends using this board with

- Power half-bridge board (KIT_LGPWR_BOM003)

- Mother board (KIT_LGMB_BOM503)

- Daughter board (KIT_LGDB_BOM003)

- Capacitor board (KIT_LGCAP_BOM003)

Target use / Applications:

Light electric vehicle (LEV) prototyping (Low speed electric vehicles, e-scooters, three-wheelers, golf carts, e-forklifts)

Features:

- Gate resistors on FR4 for ease of rework

- Additional ceramic capacitor connected to the DC bus

- Optional branch out connection for paralleling of MOSFETs

Benefits:

- Scalability and versatility

- Rapid prototyping

- Fast building of customized solutions

KIT_LGMB_BOM503

Mother board featuring EiceDRIVER™ (2EDL23N06PJ) gate driver IC for 2nd and 3rd phase

OPN: KITLGMBBOM503TOBO1

Infineon components:

- EiceDRIVER™ 600 V half-bridge gate driver IC (2EDL23N06PJ)

The mother board provides the gate driver IC for 2nd and 3rd phase but it does not include the XMC™-connector.

Interchangeable Board Approach:

Infineon strongly recommends using this board with

- Power half-bridge board (KIT_LGPWR_BOM003)

- Master mother board (KIT_LGMB_BOM003)

- Daughter board (KIT_LGDB_BOM003)

- Capacitor board (KIT_LGCAP_BOM003)

Target use / Applications:

Light electric vehicle (LEV) prototyping (Low speed electric vehicles, e-scooters, three-wheelers, golf carts, e-forklifts)

Features:

- Gate resistors on FR4 for ease of rework

- Additional ceramic capacitor connected to the DC bus

- Optional branch out connection for paralleling of MOSFETs

Benefits:

- Scalability and versatility

- Rapid prototyping

- Fast building of customized solutions

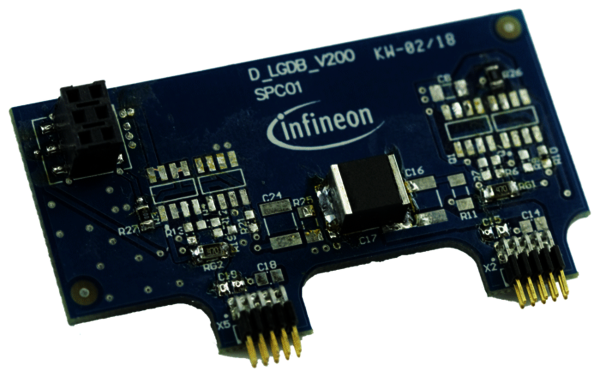

KIT_LGDB_BOM003

Daughter board, interconnecting the gate driver and the power boards

OPN: KITLGDBBOM003TOBO1

Infineon components:

none

This daughter board is supporting the LVD scalable power demo board platform. Its main function is to provide the system with the interconnection between the gate drivers and the power boards (MOSFET gates). It enables paralleling of the power boards by branching the interconnection of the gate driver signals, and providing each additional MOSFET the respective gate resistor. This board can only be used in conjunction with the LVDSPD mother boards and power boards, serving as the interconnection between the two categories when paralleling the power boards.

Interchangeable Board Approach:

Infineon strongly recommends using this board with

- Power half-bridge board (KIT_LGPWR_BOM003)

- Master mother board (KIT_LGMB_BOM003)

- Mother board (KIT_LGMB_BOM503)

- Capacitor board (KIT_LGCAP_BOM003).

Target use / Applications:

Light electric vehicle (LEV) prototyping (Low speed electric vehicles, e-scooters, three-wheelers, golf carts, e-forklifts)

Features:

- Gate resistors on FR4 for ease of rework

- Additional ceramic capacitor connected to the DC bus

- Connection for paralleling of MOSFETs

Benefits:

- Scalability and versatility

- Rapid prototyping

- Fast building of customized solutions

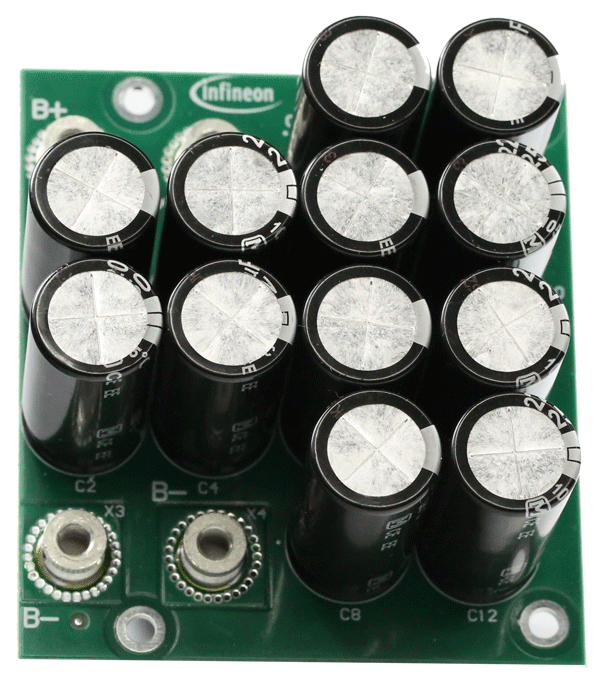

KIT_LGCAP_BOM005

Capacitor board, PCB interconnecting the 12 capacitors for the DC bus

OPN: KITLGCAPBOM005TOBO1

Infineon components:

none

This capacitor board is a supporting design for the LVD Scalable power demo board platform. It provides the system with an interconnection platform for leaded capacitors for the DC bus supplying the power half-bridges. This board can also be used in other lab setups requiring a DC capacitor bank in the range of up to 250 V.

Interchangeable Board Approach:

Infineon strongly recommends using this board with

- Power half-bridge board (KIT_LGPWR_BOM003)

- Master mother board (KIT_LGMB_BOM003)

- Mother board (KIT_LGMB_BOM503)

- Daughter board (KIT_LGDB_BOM003)

Target use / Applications:

Light electric vehicle (LEV) prototyping (Low speed electric vehicles, e-scooters, three-wheelers, golf carts, e-forklifts)

Features:

- Connectors for DC bus copper bars

- 7.5 mm radial capacitor footprint

Benefits:

- Scalability and versatility

- Rapid prototyping

- Fast building of customized solutions

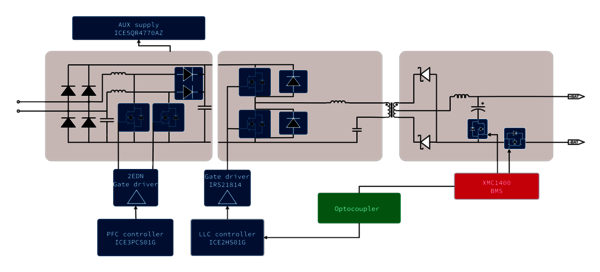

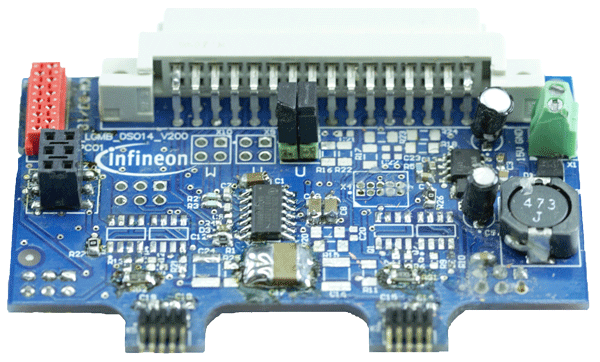

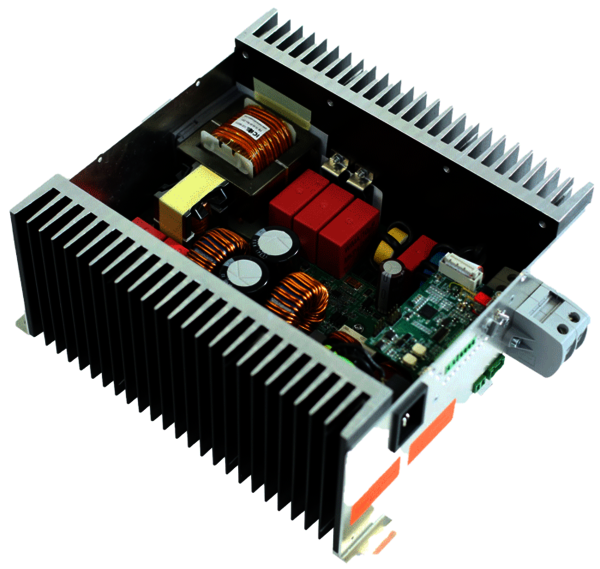

EVAL_2KW_48V_CHAR_P7

48 V lead-acid/Li-ion battery charger

2 kW high efficient natural convection cooled evaluation board based on CoolMOS™ P7

OPN: EVAL2KW48VCHARP7TOBO1

Infineon Components:

- 600 V CoolMOS™ P7 SJ MOSFETs for hard switching and soft switching topologies (IPW60R080P7, IPW60R060P7)

- CoolSiC™ Schottky diode 650 V G6 for an attractive price-performance ratio (IDH16G65C6)

- OptiMOS™ 5 80 V power MOSFET for reverse polarity protection (BSC030N08NS5)

- Controller IC for active CMM power (ICE3PCS01G)

- Resonant mode controller (ICE2HS01G)

- CoolSET™ quasi-resonant flyback controller (ICE5QR2280AZ)

- EiceDRIVER™ 2EDN non-isolated dual gate driver (2EDN7524F)

- 600 V high and low side gate driver IC (IRS21814)

- 32-bit XMC1000 industrial microcontroller (XMC1403-Q064X0200 AA)

* For assistance on how to build your customized version of EVAL_2KW_CHAR_P7 by using Infineon´s recommended components read the provided application note or contact our sales.

The 2 kW lead-acid / Li-ion industrial battery charger targets low speed electric vehicle applications (LSEV). The evaluation board uses a dual boost PFC and half-bridge LLC power supply solution with Infineon's latest CoolMOS™ P7 Superjunction MOSFET that enables natural convection cooling.

Target use / Applications:

Battery charger for e-bikes, pedal electric cycles (i.e. pedelecs), e-rickshaws, e-scooters, e-forklifts, e-(golf) carts, micro e-cars, logistics

The 2 kW lead-acid / Li-ion industrial battery charger targets low speed electric vehicle applications (LSEV). The evaluation board uses a dual boost PFC and half-bridge LLC power supply solution with Infineon's latest CoolMOS™ P7 Superjunction MOSFET that enables natural convection cooling.

Target use / Applications:

Battery charger for e-bikes, pedal electric cycles (i.e. pedelecs), e-rickshaws, e-scooters, e-forklifts, e-(golf) carts, micro e-cars, logistics EVs

Features:

- Wide range input operation 90 VAC - 265 VAC

- Capable of charging lead-acid and Li-ion batteries

- Battery capacity selection (40 Ah - 250 Ah)

Benefits:

- High efficiency - 94.5 % at full load

- Natural convection cooling

- Portable unit

Contact Us