CIPOS™ IPMs (Intelligent Power Modules) by Infineon

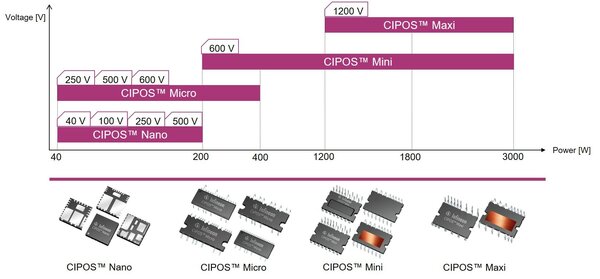

Infineon offers a variety of IPMs with different semiconductors in different packages, voltage and current classes depending on the level of integration and power to be handled. These IPMs are separated into CIPOS™ Nano, CIPOS™ Micro, CIPOS™ Mini as well as CIPOS™ Maxi families.

Why should you decide to use IPMs? They combine gate drivers and six power stages in one package, which results in less components for an improved manufacturability, less space on the PCB and higher reliability compared with discrete solutions.

CIPOS™ IPMs serve a wide range of applications from pumps and fans over home appliance to low power general purpose drives for industrial purpose.

Find the perfect fit for your industry!

Key Benefits:

- Shorter time-to-market

- Increased reliability

- Reduced system cost and space

- Improved manufacturability

Additional Links:

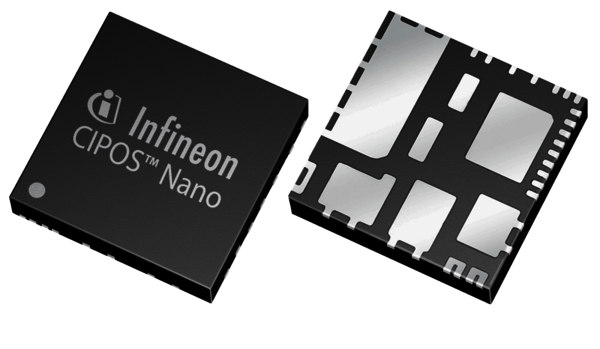

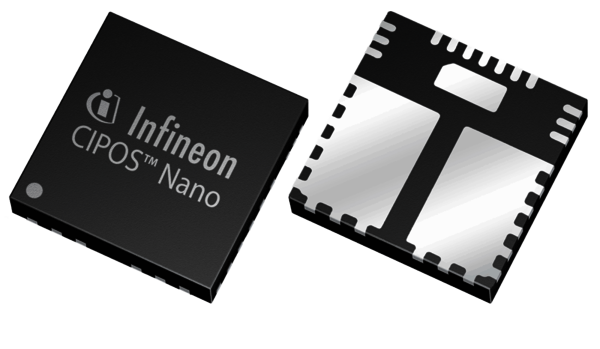

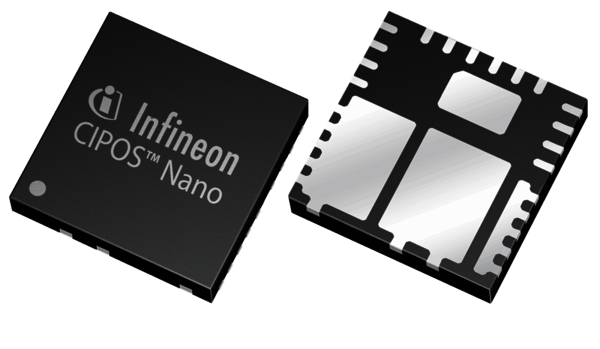

CIPOS™ Nano – Ultra Compact Three-Phase or Half-Bridge MOSFET IPMs

CIPOS™ Nano is the smallest and most compact IPM family. It can typically be found in the rectifier, converter and inverter stage in power management circuits. An example for consumer applications is the hair dryer. When talking about residential use, we mean air purifiers or ceiling fan and lastly, the CIPOS™ Nano family can be found in industrial applications such as circulation pump or ventilator.

Benefit from an innovative packaging solution that delivers a new benchmark in device size by offering up to a 60 percent smaller footprint than existing 3-phase motor control power IPMs.

The latest member in the CIPOS™ Nano family is the iMOTION™ IMM100 Smart IPM that integrates gate driver and six MOSFETS. In combination with the iMOTION™ Motor Control Engine it offers a complete motor drive system.

Key Features:

- Current rating from 0.15 A to 10 A, power rating up to 200 W

- Integrated gate driver and bootstrap functionality

- Heat sink-less operation

- Additional space saving with iMOTION™ IMM100 Smart IPM

Key Benefits:

- Cost savings from smaller footprint and reduced PCB space

- Easy implementation of 2 or 3-phase motor drives with half-bridge IPMs

- Same PCB footprint to address multiple application markets (100 – 230 VAC)

- Reduced R&D time and cost for both hardware and software with iMOTION™ IMM100 Smart IPM

Major Applications:

- Small home appliance

- Hair dryer

- Air purifier

- Ceiling fan

- Motor drives

- Battery management

- Water pump

- Aircon

CIPOS™ Nano Packages

|

Product |

Switch Type |

Voltage CLass [V] |

RDS(on) [Ω] |

Pmot (10kHz) [W] |

Configuration |

Package |

|

Mosfet |

500 |

2.2 |

70 |

3-Phase Open Source |

QFN 12x12 |

|

|

Mosfet |

600 |

0.28 |

65 |

2-Phase inverter |

QFN 12x10 |

|

|

Mosfet |

250 |

0.063 |

175 |

2-Phase inverter |

QFN 12x10 |

iMOTION™ IMM100 Smart IPM

|

Product |

Switch Type |

Voltage Class [V] |

RDS(on) [Ω] |

Pmot (10kHz) [W] |

Configuration |

Package |

|

Mosfet |

600 |

1400 |

80 |

3-Phase inverter |

QFN 12x12 |

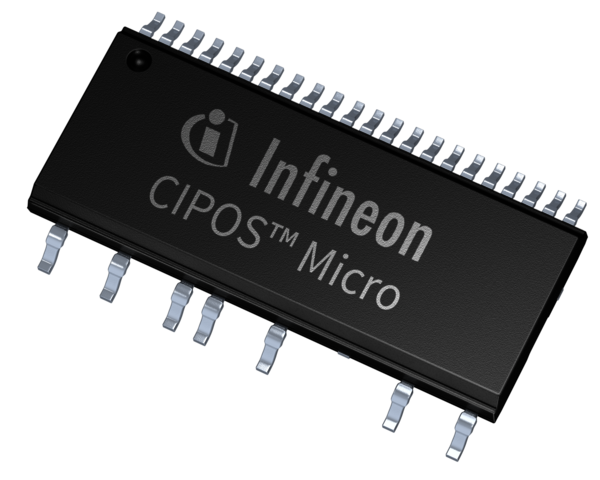

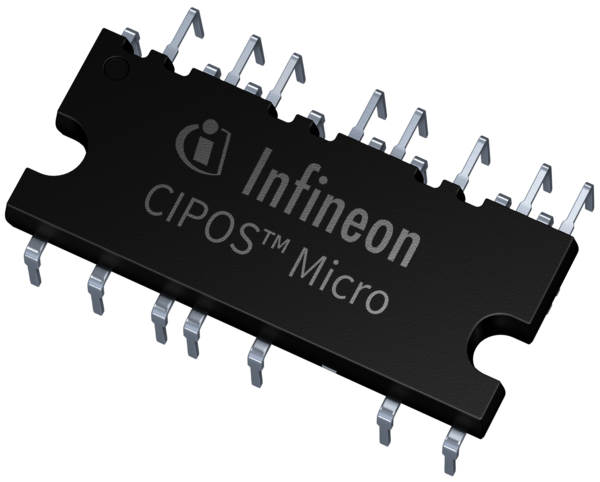

CIPOS™ Micro – Cost Effective Solution for Low Power Motor Drive Applications

The next member of the IPM family is CIPOS™ Micro, consisting of a 3-phase MOSFET or IGBT configuration including gate drivers. Typical applications are low-power motor drives for instance ventilation fans, circulation pumps, air purifiers, dish washing machines and refrigerator compressor drives.

This family uses industry standard footprints and processes and it is compatible with various PCB substrates, thus offering a cost-effective power solution. It features rugged and efficient high voltage IGBTs and MOSFETs that have been enhanced for variable frequency drives with voltage ratings of 250 V, 500 V and 600 V. In combination with high voltage driver ICs, CIPOS™ Micro achieves an optimal balance between switching losses and EMI.

CIPOS™ Micro offers DC current ratings of up to 6 A and can drive motors up to 100 W without heatsink and up to 450 W with heatsink. The package options are both through-hole and surface mount.

Key Features:

- 3-phase MOSFET or IGBT configurations including gate drivers

- Various lead forms available including through-hole and surface mount

- Advance input filter with shoot-through protection

- Under-voltage lockout for all channels

- UL-certified NTC thermistor

Key Benefits:

- Ease of design and fast-time-to-market

- Address 20 W to 450 W with the same footprint

- Lower losses than similar modules in the market

Key Applications:

- Air purifier

- Ceiling fan

- Hair dryer

- Kitchen hoods

- Aircon

- Fridge

- Dishwasher

- Blender

CIPOS™ Micro Packages

|

Product |

Switch Type |

Voltage Class [V] |

Rated Current [A] |

Pmot (10 kHz) [W] |

Configuration |

Package |

|

IGBT |

600 |

4 |

320 |

3-Phase Open Emitter |

DIP 29x12 |

|

|

IGBT |

600 |

6 |

400 |

3-Phase Open Emitter |

SOP 29x12 |

|

|

IGBT |

600 |

4 |

250 |

3-Phase Open Emitter |

DIP 29x12 |

|

|

IGBT |

600 |

4 |

250 |

3-Phase Open Emitter |

SOP 29x12 |

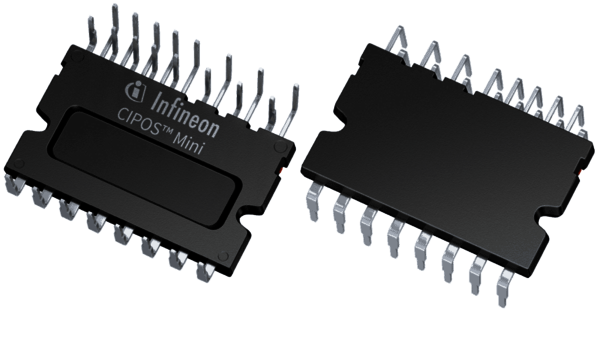

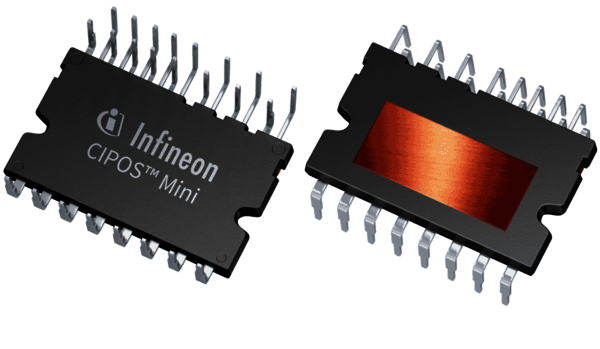

CIPOS™ Mini – Energy Efficient Solution for a Wide Range of Applications from PFC to Inverter

CIPOS™ Mini is a family of high efficient intelligent power modules that has highest power density with 4 A to 30 A rated products built into a single package platform. It integrates various power and control components to increase reliability, optimize PCB size and system costs. Utilizing multiple configurations, CIPOS™ Mini IPMs are applicable to the wide applications to control variable speed drives, such as air conditioners, washing machines, refrigerators, vacuum cleaners, compressors, and industrial drives up to 3 kW.

The configurations offered within the CIPOS™ Mini family are 2-phase MOSFET, 3-phase MOSFET and IGBT, integrated PFC and 2-phase and 3-phase interleaved PFC. All options include an integrated gate driver and built-in temperature monitoring. CIPOS™ Mini provides optimized performance for power applications, which need good thermal conduction and electrical isolation, but also EMI-safe control, innovative FAULT indication and overload protection.

The latest member within the CIPOS™ Mini family is the IM564 series. It incorporates a CoolMOS™ Power MOSFET and a rapid switching diode for the PFC stage to increase PFC switching frequency up to 150 kHz. This enables significant inductor size reduction for high power density with small system size.

Key Features:

- 2-phase, 3-phase and PFC configurations including gate driver

- Current rating ranging from 4 – 30 A, power rating up to 3 kW

- Dual-in-line transfer molded package

- Advanced protection features

- Rugged SOI gate driver IC technology

Key Benefits:

- Easy power extension from 300 W to 3 kW

- Optimized performance for each application

- Enhanced robustness of the advanced IGBT and gate driver IC technology

- High power density

- Two substrate types provide a cost-efficient solution for home appliances and motor drives.

Key Applications:

- Refrigerators

- Air conditioners

- Washing machine

- Dishwasher

- Laundry dryer

- Vacuum cleaner

- Fans

- Heating, ventilation and air conditioning (HVAC)

- General purpose drives

CIPOS™ Mini Packages

|

Product |

Switch Type |

Voltage Class [V] |

Rated Current [A] |

Pmot (10 kHz) [W] |

Configuration |

Package |

|

IGBT |

600 |

6 |

800 |

3-phase open emitter |

DIP 36x21 |

|

|

IGBT |

600 |

15 |

1600 |

3-phase open emitter |

DIP 36x21 |

|

|

IGBT |

600 |

20 |

2400 |

3-phase open emitter |

DIP 36x21D |

|

|

IGBT |

600 |

30 |

2600 |

3-phase open emitter |

DIP 36x21D |

|

|

IGBT |

600 |

20 |

400 |

PFC-integrated 3-phase |

DIP 36x21D |

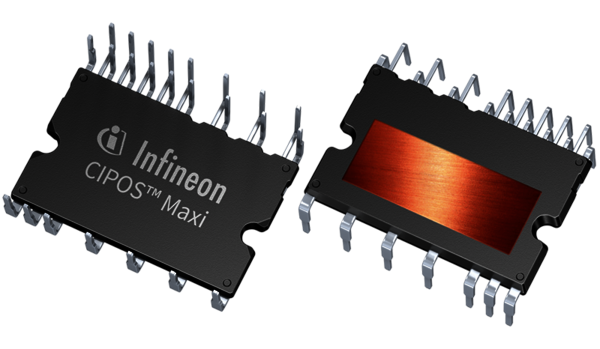

CIPOS™ Maxi – Solutions for High Reliability and Performance Application

The high-performance CIPOS™ Maxi IPMs integrate various power and control components within one package to increase reliability and to optimize PCB size and system costs. CIPOS™ Maxi IPMs are designed to control three-phase AC motors and permanent magnet motors in commercial applications such as low power General Purpose Inverters (GPI), pumps, fans, and active filters for HVAC (heating, ventilation and air-conditioning). The product concept is specially adapted for power applications which need good thermal performance and electrical isolation, as well as good EMI performance and overload protection.

This portfolio includes 1200 V, 5 A and 10 A options for up to 1.8 kW motor drive solutions. CIPOS™ Maxi has achieved the smallest package in 1200 V IPM class while still offering high power density and best performance.

Key Features:

- 3-phase IGBT configuration including gate driver

- Fully isolated dual in-line molded module with DCB

- 1200 V TRENCHSTOP™ IGBT4

- Various protection mechanisms such as under-voltage lockout, cross-conduction prevention and over-current shutdown

Key Benefits:

- Smallest package size in 1200 V IPM class with high power-density and best performance

- Enhanced robustness of gate driver technology for excellent protection

- Adapted to high switching application with lower power loss

- Simplified design and manufacturing

Key Applications:

- Pumps

- Blowers

- Fans

- Low-power general purpose drives

- Heating ventilation and air conditioning (HVAC)

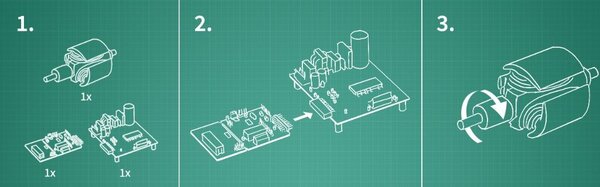

CIPOS™ IPM Evaluation Boards – Get Your Motor Running in Less than 1 Hour!

Modular Application Design Kits (MADK) are a full motor drive solution. Customers can evaluate the CIPOS™ IPMs quickly and easily without having to spend time on the system design. All MADKs work with iMOTION™ motor control ICs to get the motor running in less than 1 hour without the need for any coding.

The MADK evaluation platform is divided into control boards and power boards and it can cover motor drive applications up to 2.5 kW. All control and power boards can be connected with the M1 20pin interface connector or the M3 30pin interface connector for PFC.

Choose between different power boards and combine them with the preferred controller board. Simply select the required voltage used in your system between 24 – 230 V, the power rating or the special functions (like active PFC) for your motor drive application.

Drastically reduce customers’ development cost and time-to-market thanks to full inverterized motor drive system solution.

Key Features:

- Complete power stage to drive any motor

- Different power boards up to 2.5 kW output power

- Compatible with worldwide power grid standard 110 V and 220 V

- M1/M3 interface connector

- Motor drive and PFC capability

Key Benefits:

- Drive any motor in less than one hour

- Fast time-to-market – reduced design time & effort for hardware and software

- Class B qualified motor drive software

- Standard iMOTION™ MADK platform enables modularity, flexibility and scalability

- Scalable power levels with CIPOS™ Nano, CIPOS™ Micro, CIPOS™ Mini and CIPOS™ Maxi

Board

EVAL-M1-101T

Description

iMOTION™ MADK control board with M1 connector powered by IMC101T-T038 iMOTION™ motor control IC

EVAL-M3-102T

iMOTION™ MADK control board with M3 connector powered by IMC102T-F064 iMOTION™ motor control IC

EVAL-M1-36-45A

MADK inverter power board powered by IRSM836-045MA CIPOS™ Nano, 3-phase IPM for motor power up to 85 W. Combine with control boards equipped with the M1 20pin interface connector, such as EVAL-M1-101T

EVAL-M1-IM231

MADK inverter power board powered by IM231-L6S1B CIPOS™ Micro, 3-phase IPM for motor power up to 400 W. It can be combined with the EVAL-M1-101T, a control board with M1 20pin interface connector.

EVAL-M1-CM610N3

MADK inverter power board powered by IKCM10H60GA CIPOS™ Mini, 3-phase IPM. In combination with control boards equipped with the M1 20pin interface connector, like EVAL-M1-101T you can run a motor up to 750 W.