Infineon Technologies Silicon Carbide CoolSiC™ MOSFETs & Diodes

As the leading power supplier with 20 years of experience in Silicon Carbide (SiC) technology development, Infineon provides a portfolio that addresses the need for smarter, more efficient energy generation, transmission and consumption.

The portfolio addresses customers’ needs for reduced system size and cost in mid- to high-power systems, while meeting the highest quality standards, long system lifetime and providing guaranteed reliability. With CoolSiC™, customers will reach the most stringent efficiency targets while seeing a drop in operational system cost.

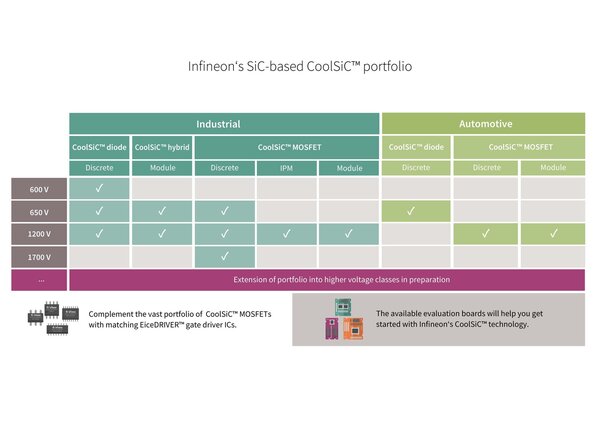

Portfolio

The portfolio is comprised of CoolSiC™ Schottky diodes, CoolSiC™ hybrid models, CoolSiC™ MOSFET modules and discretes, plus EiceDRIVER™ gate driver ICs for driving Silicon Carbide devices.

Infineon's CoolSiC™ Schottky Diodes provide a relatively high on-state resistance and leakage current. In SiC material, Schottky diodes can reach a much higher breakdown voltage. The Infineon portfolio of SiC Schottky products covers 600V and 650V to 1200V Schottky diodes.

The combination of a fast silicon based switch with a CoolSiC™ schottky diode is often termed a “hybrid” solution. In recent years Infineon has manufactured several millions of hybrid modules and has seen them installed in various customer products in applications like e. g. solar and UPS.

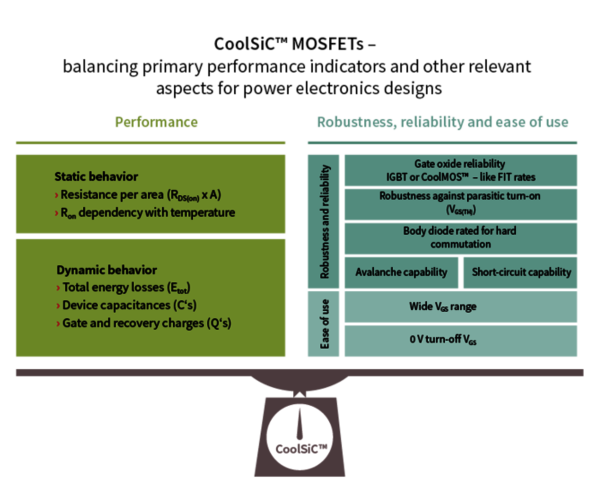

CoolSiC™ MOSFETs are built on a state-of-the art trench concept that sets a benchmark - allowing for both lowest losses in the application and highest reliability in operation.

Features

What are the Technical Features of Infineon SiC MOSFETs?

The CoolSiC™ MOSFET modules are available in 1200V, while the SiC MOSFETs in discrete housing come in 650, 1200 and 1700V. The latest addition to the portfolio is the CIPOS™ Maxi 1200V CoolSiC™ MOSFET based intelligent power module (IPM)

- Superior gate oxide reliability

- Stable, robust body diode

- Excel in in hard-switching topologies e.g. servo drives

- Lowest switching losses at fast switching speed

- Easy design-in thanks to robustness against parasitic turn-on effects

- Short-circuit rating 3µs

- Excel in soft-switching topologies e.g. EV charging

- Lowest switching losses and easy design-in

- 0V turn-off can be applied

Applications

What are the Application Benefits of Silicon Carbide?

CoolSiC™ MOSFET in solar applications…

- … doubles the inverter power at same inverter weight

- … has a significantly less efficiency reduction at high operating temperature compared to Si-based alternatives

- … offers a power density increase by a factor of up to 2.5

- … shows a maximum efficiency of more than 99%

CoolSiC™ MOSFET in energy storage systems…

- … cuts losses by up to 50%

- … increases the energy by up to 2% without increasing battery size

CoolSiC™ MOSFET in server and telecom power…

- … cuts losses by up to 30%

- … doubles the density for reachin

CoolSiC™ MOSFET in EV Charging…

- … cuts charging time in half

- … reduces the component number by 50% yet boosting efficiency

- … lowers the cost of ownership due to higher efficiency

- … reduces the cooling effort

CoolSiC™ MOSFET in xEV Applications:

For the main inverter it…

- … increases the battery utilization by 5-10%

- … increases power density for system size reductions of up to 80%

- … lowers conduction losses in light load condition compared to Si-IGBTs

In on-board chargers Silicon Carbide…

- … is able to realize smaller bidirectional 3phase chargers

- … helps downsizing passive components thanks to faster switching

- … enhanced efficiency in PFC and DC-DC stage of up to 1%

In HV DC-DC converters CoolSiC™ MOSFETs…

- … offers higher switching frequencies

- … enhances power density

- … increases the level of integration

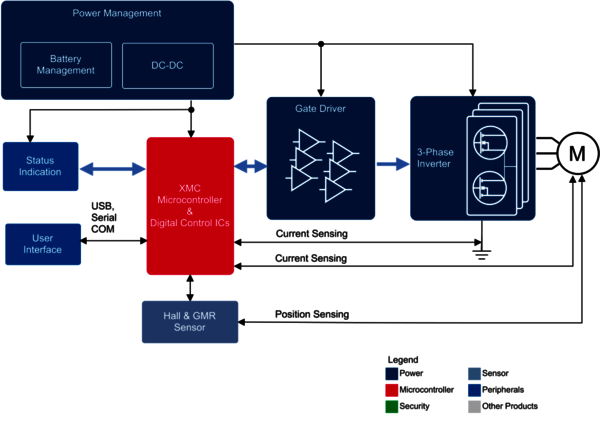

Which Gate Drivers are Recommended for Driving a Silicon Carbide MOSFET?

To achieve maximum system benefits when using SiC MOSFETs, it is advisable to complement them with Infineon’s EiceDRIVER™ gate-driver ICs to fully leverage the advantage of SiC technology. By doing so, customers will achieve improved efficiency, space and weight savings, part count reduction and enhanced system reliability.

Customers may choose between different EiceDRIVER™ gate-driver types including:

- Single-channel high-side compact gate driver

- Single- and dual output enhanced driver with short-circuit protection

- Slew-rate control high-side driver for toughest requirementsrameters:

Infineon’s SiC MOSFET drivers impress with the following parameters:

- Availability in wide-body package with 7.6mm creepage distance

- Suitability for operation at high ambient temperature

- Active Miller clamp

- Short-circuit clamping and active shutdown

- ≥ 100kV/μs CMTI (1EDU20I12SV: ≥ 50kV/μs CMTI)

- Precision short-circuit protection (via DESAT)

- 12V/11V typical UVLO thresholds

Associated Evaluation Boards

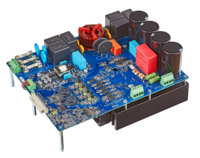

1. The EVAL-M5-IMZ120R-SIC includes a 3-phase Silicon Carbide MOSFET for motor drive applications. In combination with control boards equipped with the M5 32-pin interface connector such as the XMC DriveCard 4400, it features and demonstrates the CoolSiC™ MOSFETs in this application. The evaluation board was developed to support customers during their first steps designing applications with the CoolSiC™ MOSFET 1200V in discrete packages, such as the IMW120R045M1, and EiceDRIVER™ 1200V isolated gate driver 1EDI20H12AH.

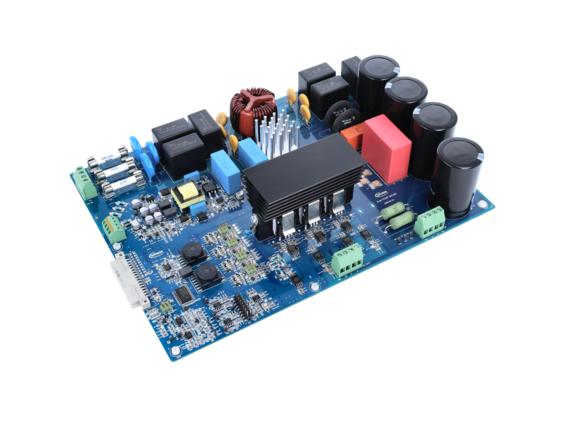

2. EVAL_PS_SIC_DP_MAIN (mother board) is a CoolSiC™ MOSFET 1200 evaluation platform including EiceDRIVER™ gate driver IC demonstrating the switching behavior and driving options of the CoolSiC™ MOSFET IMZ120R045M1 in TO247 4-pin package. It was designed for a max voltage of 800V and a max pulsed current of 130A. By adopting a modular approach it can be expanded with currently two drive cards (more to come).

The first drive card (REF_PS_SIC_DP1) contains the EiceDRIVER™ 1EDC Compact 1EDC20I12MH with an integrated active Miller clamp preventing parasitic turn-on.

The second drive card (REF_PS_SIC_DP2) includes the EiceDRIVER™ 1EDC Compact 1EDC60H12AH allowing a bipolar supply, where VCC2 is +15V and GND2 is negative.

3. In combination with control boards equipped with an M5 32-pin interface connector such as the XMC DriveCard 4400, the EVAL-M5-E1B1245N-SIC features and demonstrates Infineon’s CoolSiC™ MOSFET technology and the respective use / performance in motor drives.

The evaluation board was developed to support customers during their first steps designing applications with the sixpack power module FS45MR12W1M1_B11. The module has a rated blocking voltage of 1200V at a typical on-state resistance of 45mΩ. It is optimized for motor drive applications with a very high-frequency switching operation.

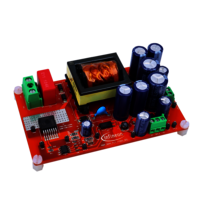

4. The reference board REF_62W_FLY_1700V_SIC supports customers designing auxiliary power supplies for three phase converters using the 1700V CoolSiC™ MOSFET in a single-ended flyback topology.

The REF-62W_FLY_1700V_SIC works in quasi-resonant mode and has a peak efficiency of 90.56% at a full load specification.

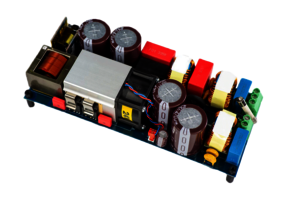

5. The EVAL_3K3W_TP_PFC_SIC is a system solution for bridgeless totem-pole power factor correction (PFC) with bidirectional power capability. It is enabled by Infineon’s CoolSiC™ trench power MOSFET and CoolMOS™ superjunction power MOSFETs as well as isolated drivers and an XMC™ microcontroller.

Target applications are those requiring high efficiency (~99%) and high power density (72W/in3), such as high-end server and telecom. In addition, the bidirectional power flow capability allows addressing battery chargers or battery formation applications, too.

The integrated totem-pole operates in continuous conduction mode (CCM) in both, rectifier (PFC) and inverter mode which also implements digital control on Infineon’s XMC™ 1000 series microcontroller.

Infineon Technologies CoolSiC™ Trench Power MOSFETs

Silicon Carbide MOSFETs offering Reliable and Cost-effective Performance in Discrete Packages: TO-247-3/4 Pin and TO-263-7 Package.

- IMBF170R1K0M1XTMA1

- IMW120R140M1HXKSA1

- IMZA65R072M1HXKSA1

- IMW65R027M1HXKSA1

- IMZ120R030M1HXKSA1

- IMZA65R048M1HXKSA1

- AIMW120R045M1XKSA1

- IMBG120R090M1H

Infineon Technologies CoolSiC™ Trench Power MOSFETs Modules

1200V Silicon Carbide MOSFET Power Modules in Easy and 62mm Housing open up New Opportunities for Inverter Designers to realize efficiency and power density. The CIPOS™ Maxi IPM offers the chance for integrating various power and control components to increase reliability, optimize PCB size and system costs

- FF3MR12KM1HOSA1

- FF2MR12KM1HOSA1

- FS45MR12W1M1B11BOMA1

- F3L15MR12W2M1B69BOMA1

- F423MR12W1M1B11BOMA1

- FF08MR12W1MA1B11ABPSA1

- IM828-XCC

Infineon Technologies CoolSiC™ Schottky Diodes

600V, 650V and 1200V Silicon Carbide Schottky Diode provide a Relatively High on-state Resistance and Leakage Current.

- IDK02G120C5XTMA1

- IDDD04G65C6XTMA1

- IDK08G65C5XTMA2

- IDWD10G120C5XKSA1

- IDK16G120C5XTMA1

- IDWD40G120C5XKSA1

Infineon Technologies CoolSiC™ Hybrid Modules

Combination of an IGBT Chip and a CoolSiC™ Schottky Diode to further extend the Capability of IGBT Technology.

- F3L400R10W3S7FB11BPSA1

- FS3L200R10W3S7FB11BPSA1

- FS3L30R07W2H3FB11BPSA2

Infineon Technologies EiceDRIVER™ Gate Driver ICs

Ultra-fast CoolSiC™ MOSFETs typically are best driven by Gate-driver ICs with integrated Galvanic Isolation.

- 2EDF9275FXUMA1

- 2EDS9265HXUMA1

- 2ED020I12F2XUMA1

- 1ED3431MU12MXUMA1

Contact Us