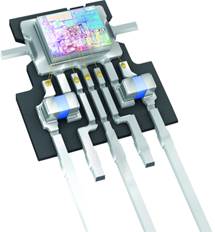

HAC 37xy: Multi-Axis Hall Sensor With Integrated Capacitors

The HAC 37xy Hall-effect sensor offers high-precision angle and linear position measurement in a TO92UF leaded package with integrated capacitors for demanding automotive and industrial applications.

Thanks to HAC 37xy you will design PCB-free module solutions with high EMI and ESD protection.

The singlepackage solution from TDK-Micronas enables very robust, accurate and steady placement of the sensor in customer modules.

Jens Schubert (Manager Marketing Automotive at TDK-Micronas) and Markus Balke (Senior Marketing Manager Analog & Sensor at Rutronik) talk at the Sensor+Test Exhibition 2016 about TDK-Micronas' 2nd generation 2D sensor family HAC 37xy.

HAC 37xy a Key Sensor in Powertrain Applications

Lower fuel consumption and reduced CO2 / NOX emissions with unchanged engine power are the main drivers for the increased use of variable geometry turbochargers and EGR valves in the cars.

In the last 10 years, many applications have been significantly improved in the power train thanks to fully automated control systems. Thereby, high-precision sensors provide the position of various actuators in the engine area.

In the past, a majority of these sensors have been based on one-dimensional, linear Hall-effect sensors. Meanwhile, the trend is to utilize direct angle sensors which allow a temperature stable multidimensional angle measurement with elementary magnetic circuits.

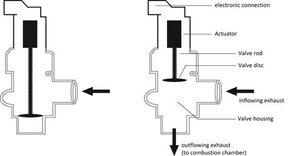

EGR works by recirculating a portion of the engine’s exhaust gas back into the engine cylinders leading to reduced fuel consumption of the vehicle and less CO2 emissions. The engine control unit needs an actual position of the EGR valve to get an accurate and efficient control. The EGR Valve working principal is based on a linear displacement of a valve rod (see Fig. 1). The typical range of measurement is of 10mm.

Such distance with an ambient temperature up to 160°C (320 °F)can be precisely measured by a 2D Hall: either directly via linear displacement measurement of a small bar magnet or via rotational movement by means of a single disc magnet.

What are the Key Features of HAC 37xy for EGR and Turbocharger ?

The two capacitors assembled in the sensor package have a value of 100 nF and can reliably work in ambient temperatures up to 160 °C (320 °F). This is particularly important in applications such as EGR, turbo actuators or bypass valves, because exhaust gas systems are exposed to higher temperatures. The capacitors meet the demanding EMC requirements in the 50 V-version. Compared to competitors solutions, the HAC 37xy can withstand the hard General Motors GMW3097 85-V-pulse (DCC) without any further passive components.

The HAC 37xy has been classified as Class A (A = max. ± 50 mV output deviation) for immunity BCI tests up to 300 mA according to ISO 11452-4 (open-loop) and PSA B21-100-C (closed-loop).

Thanks to his "virtual offset feature", the HAC 37xy is the perfect solution for linear measurement required in applications as EGR and Turbo charger. It allows increasing the accuracy or reducing the system cost by using smaller magnets: for example a magnet with 5 mm length~ can achieve <1% linearity error over the full temperature range of -40 °C to 160 °C (-40 °F to 320 °F).

By using the Hall sensor with SENT interface, the HAC 37xy is able to transmit the chip-temperature and the position information via the "fast channel" or over several frames via the "Slow-Channel". The temperature information is very important in the exhaust area and it saves the use of a separate temperature sensor.

Target Applications:

- EGR valve position

- Transmission position

- Cylinder and valve position sensing

- Gear selector

- Turbo-charger

- Throttle valve position,

- Chassis position sensors (ride-height control) with HAC 3715

What are the Benefits?

Wastegate actuators or variable-geometry turbocharger provide fuel reduction thanks to the so-called "downsizing" of engines.

Turbochargers use moveable valves to adjust the air-flow to the turbine. The valves are placed just in front of the turbine and their angle is adjusted by an actuator to block or increase air flow to the turbine. This variability maintains a comparable exhaust velocity and back pressure throughout the engine.

The result is that the turbocharger improves fuel efficiency, especially at low speeds, as more air is pushed into the cylinder through the turbocharger; this increases the power and the torque with reduced consumption. As for the EGR, the position of the valve is required and it is perfectly delivered by a direct angle Hall sensor.