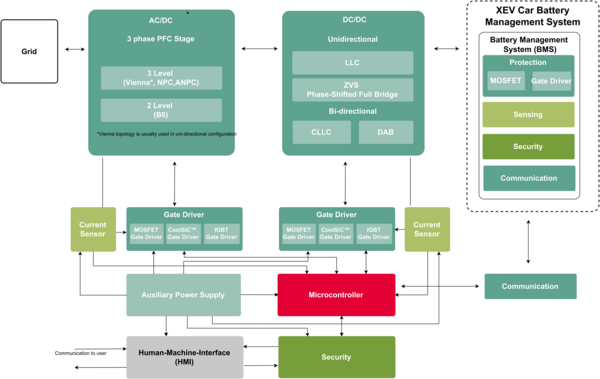

High-Power Solutions for Fast EV Charging from Infineon

From Power and Control to Sensor and Security

Along with the ever-growing number of electric vehicles on the market and pressure from governments to reduce vehicle emissions to zero latest by 2050, there is a strong need for more efficient charging solutions. As various consumer studies show, the acceptance of electromobility very much depends on the availability and duration of the charging process, high-power DC charging stations are the answer to these market requirements. Already today, a typical EV can charge about 80% of its battery capacity in less than 10 minutes. This is comparable to refueling a conventional car with internal combustion engine.

As the market leader in power electronics, Infineon helps you to bring energy-efficient DC fast charging designs to life. Benefit from one of the most comprehensive, ready-to-implement one-stop product and design portfolios on the market that covers the entire product range from power conversion, microcontrollers, security, auxiliary power supply, and communication.

Advanced solutions from control to sensing to next level security and connectivity

For DC EV charging designs up to 150kW, Infineon’s discrete products offer the best price/performance ratio. These include the 600V CoolMOS™ SJ MOSFET P7 and CFD7 families, 650V IGBT TRENCHSTOP™ 5 and 1200V CoolSiC™ MOSFET. Infineon’s CoolMOS™ and CoolSiC™ MOSFETs matchless advantages include high frequency operation, high power density and reduced switching losses, allowing you to reach high levels of efficiency in any battery charging system. Infineon’s portfolio of high voltage switches is complimented by 650V and 1200V CoolSiC™ Schottky diodes. Since every switch needs a driver, and every driver needs to be controlled, they also offer the matching EiceDRIVER™ gate driver as well as XMC™ and AURIX™ microcontrollers for EV charging designs. OPTIGA™ products complete the portfolio and ensure data protection and security. Chargers in the power range above 50kW are typically built with IGBTs CoolSiC™ MOSFETs and diode power modules, e.g. CoolSiC™ Easy Modules, IGBT EconoPACK™ and the IGBT EconoDUAL™ family. Charger piles with a capacity of more than 100kW are usually built in a modular approach with stacked sub-units. Already today, these sub-units have reached a capacity of 20-50kW each and will go beyond this in future designs.

Products

Half-bridge 1200V CoolSiC™ MOSFET Module

The EasyDUAL™ 1B 1200V, 11mΩ half-bridge module with CoolSiC™ MOSFET, NTC, PressFIT Contact Technology and aluminium nitride ceramic allows for better thermal conductivity of DCB material (RthJH improvement by 40% possible), power density and compact design.

650V TENCHSTOP™ 5 H5 IGBT

The combination of ultra-fast TRENCHSTOP™ 5 H5 IGBT with half-rated freewheeling SiC Schottky barrier diodes in CoolSiC™ Hybrid discrete enables unprecedented reduction of total switching losses and allows to increase significantly switching frequency.

600V CoolMOS™ CFD7

The 600V CoolMOS™ CFD7 is Infineon’s latest high voltage superjunction MOSFET technology with integrated fast body diode. It comes with reduced gate charge (Qg), improved turn-off behavior, a reverse recovery charge (Qrr) of up to 69% lower compared to the competition, as well as the lowest reverse recovery time (trr) in the market.

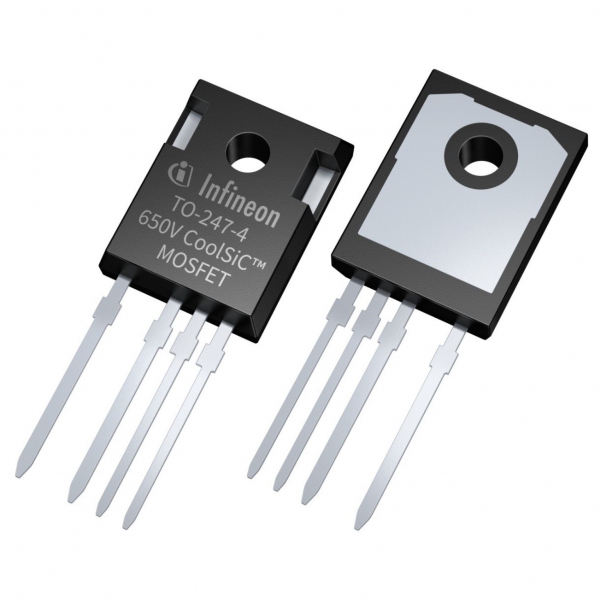

650V CoolSiC™ MOSFET

The IMZA65R027M1H CoolSiC™ MOSFET 650V is optimized to allow no compromises in getting both the lowest losses in the application and the highest reliability in operation. This SiC MOSFET comes in a TO247 4-pin package that reduces parasitic source inductance effects on the gate circuit enabling faster switching and increased efficiency.

EiceDRIVER™ Compact

Every switch needs a driver, and the right driver makes a difference. The EiceDRIVER™ Compact isolated driver family (i.e. 1ED31xx) is available with Miller clamp or separate output function. It offers reinforced isolation options (VDE-11 & UL 1577) and high current capability (14A / 9A).

EiceDRIVER™ 2EDS8265H

The EiceDRIVER™ 2EDS8265H is a reinforced isolated gate driver for secondary-side control over the mandatory safe isolation barrier in SMPS. It allows for improved thermal behavior at smaller form factor, efficiency gain and lower losses.

DC EV Charger - The Future of Electric Mobility

Get in Contact with our Experts